Professional 12V & Light Bar Wiring Loom Kits | Custom Design & Assembly

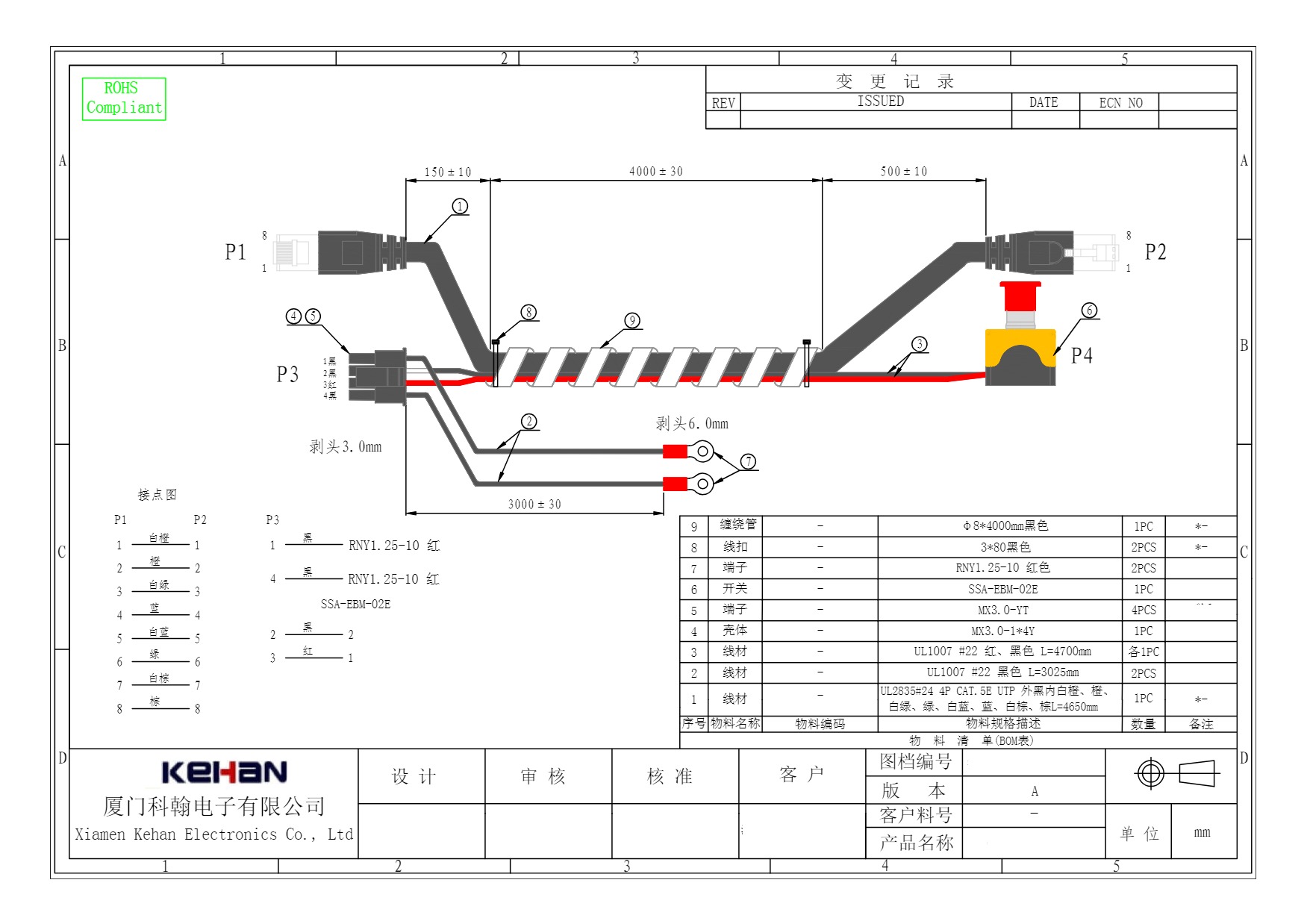

We specialize in end-to-end wiring loom solutions, combining expert wiring loom design with precision wiring loom assembly for automotive, off-road, and marine applications. Our durable 12v wiring loom systems deliver reliable power distribution for vehicles, trailers, and solar setups, featuring corrosion-resistant terminals and clear documentation. For enhanced visibility, we offer dedicated light bar wiring loom kits with waterproof connectors, built-in relays, and plug-and-play installation for LED light bars and auxiliary lighting.

All looms are engineered for safety and ease of use, supporting both professional installations and DIY projects. Custom options include length adjustments, switch integration, and shielding for demanding environments.

Illuminate your path with confidence—request a free wiring diagram or custom kit quote today!

- KenHan

- Xiamen City, Fujian Province, China

- 3 ~ 4 weeks

- Information

- Video

Professional Custom & OEM Wire Harness Solutions | Reliable Wire Harness Factory

We specialize in end-to-end wiring loom solutions, combining expert wiring loom design with precision wiring loom assembly for automotive, off-road, and marine applications. Our durable 12v wiring loom systems deliver reliable power distribution for vehicles, trailers, and solar setups, featuring corrosion-resistant terminals and clear documentation. For enhanced visibility, we offer dedicated light bar wiring loom kits with waterproof connectors, built-in relays, and plug-and-play installation for LED light bars and auxiliary lighting.

All looms are engineered for safety and ease of use, supporting both professional installations and DIY projects. Custom options include length adjustments, switch integration, and shielding for demanding environments.

Illuminate your path with confidence—request a free wiring diagram or custom kit quote today!

Key Features & Benefits:

High-Conductivity Conductors: Utilizing 99.99% oxygen-free copper for high purity, low resistance, anti-aging properties, and extended service life. This ensures minimal energy loss, reduced heat generation, and superior current load capacity.

Durable Insulation & Sheathing: Made from environmental protection high-strength PVC or neoprene, offering excellent abrasion resistance, tensile strength, corrosion resistance, waterproofing, flame retardancy, oil resistance, and weather ability. Ideal for both indoor and outdoor use, even in harsh or moving environments.

Stringent Quality Control: Guarantees uniform thickness of insulation and sheath with very low eccentricity. Each harness undergoes high-voltage testing to ensure no breakdowns, providing ultimate safety and reliability.

Available Configurations: Choose from sheath colors including all black, white inner with orange outer, white inner with black outer, or white inner with blue outer.

Certifications & Testing: Our products comply with CCC, CE, ISO9001:2008, and ROHS standards. They have passed third-party tests for high-temperature resistance (105°C), low-temperature resistance (-40°C), and flame retardancy.

Common Specifications: Available in cross-sections from 10mm² to 120mm² (10mm, 16mm, 25mm, 35mm, 50mm, 70mm, 95mm, 120mm) to meet diverse power requirements.

Applications: Perfect for use as welding cable, torch wire, welding machine wire, battery cables, power leads for cutting tools, and grounding applications.

Request a free quote for your custom wiring harness needs and experience the difference in quality and performance!

Specification

| Wire Type | VDE Cable,Dran Chain Cable, UL Wire,Medical Cable,ect. |

| Wire Size | 2AWG-32AWG,0.01mm2-50mm’ are available. |

| Wire Cores | 1 Core~50 cores are available. |

| Conductor | Bare Copper, Tinned copper, Silver Plated, Gold plated wire. |

| Rate Temperature | 80'C,105'C,125°C,180'C,220'C,300'C(176°F-572°F). |

| Protection | Waterproof, Low Smoke Halogen-Free, Anti-UV cable, Acid and alkali-resistant cable are available. |

| Certification | UL, VDE, CE IS0 or Customize Special Cables. |

| Raw materials | All parts and processing is compliant with ROHS,CCC. |

| Application | Electronics, intelligent robots, lighting, new energy, intelligent appliances. |

| Testing | 100% electrical performance tested before delivery. |

Customizing the wiring harness only requires four steps!

1:Please provide your design drawings, specifications, or samples.

2:We will review the drawings and provide you with the most competitive quote.

3:Upon your confirmation of the drawings and price, we can proceed with mass production or provide you with a sample first to ensure quality.

4:Finally, we will carefully package and ship your order promptly via the fastest available method.

product display:

Our factory and production lines

FAQ

Q1:How to make a wiring loom?

Q2:How to design a wiring harness?

A:To design a wiring harness, start by defining electrical requirements (current, voltage, signals) and environmental conditions. Use CAD software to create schematics and layout diagrams, specifying wire gauges, connectors, fuses, and protection components. Consider routing, bend radii, and strain relief. Select materials for shielding (sleeving, conduit) and securing (ties, tape). Prototype, then test for electrical performance, durability, and compliance with standards (e.g., IPC/WHMA-A-620). Finalize manufacturing documentation for efficient assembly, ensuring reliability, safety, and ease of installation in automotive, industrial, or electronic applications.

Q3:How does a wiring loom work?

A:A wiring loom (or harness) works by consolidating multiple individual wires and cables into a single, organized bundle. It efficiently transmits electrical power and signals between components while providing physical protection against abrasion, heat, moisture, and vibration. By integrating connectors, fuses, and shielding, it ensures reliable connectivity, simplifies installation, reduces wiring errors, and improves serviceability across applications like vehicles, machinery, and electronics. Its structured design enhances safety and durability in complex electrical systems.