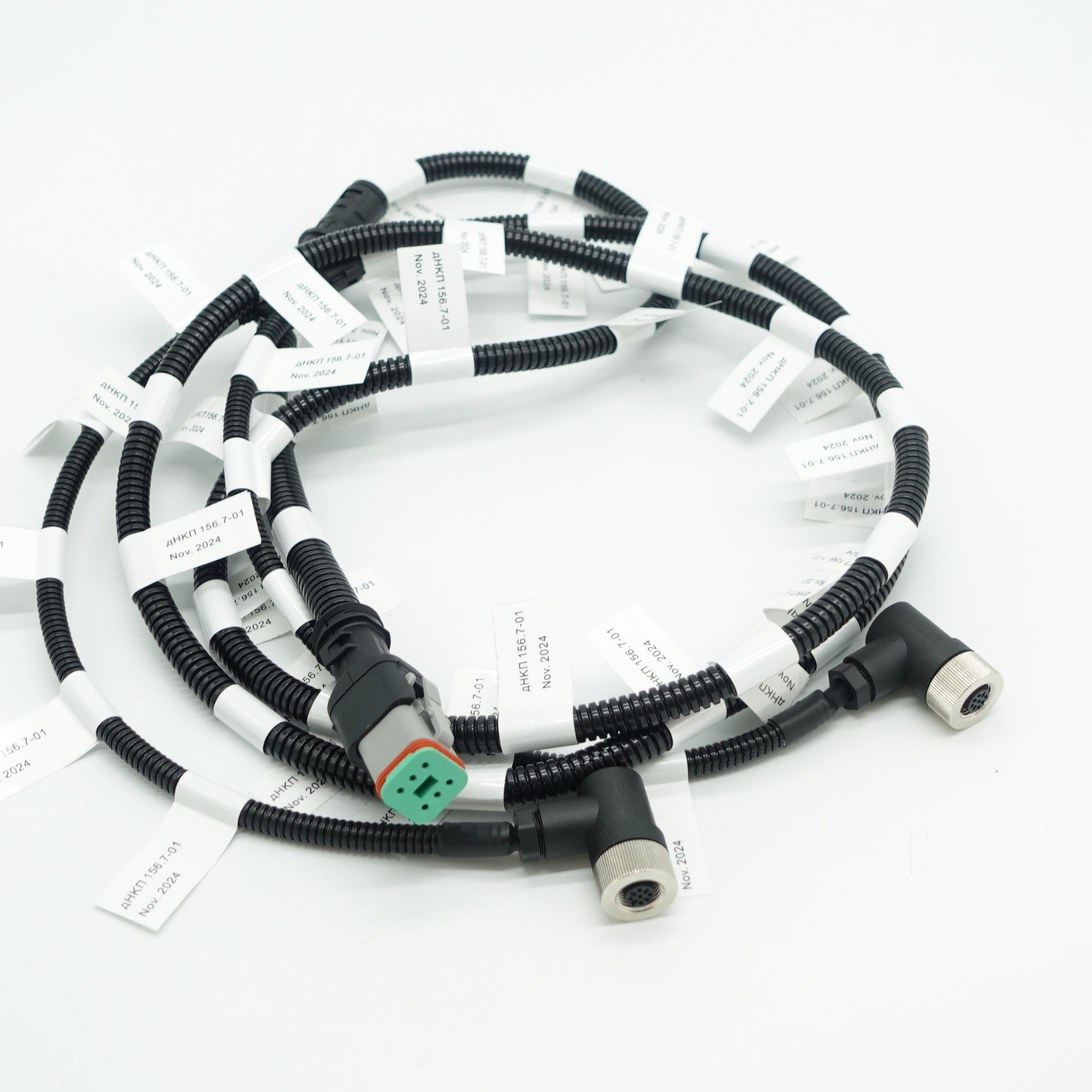

oem odm custom electrical wiring harness manufacturers

We deliver high-performance custom electrical harness systems engineered for industrial machinery, commercial trailers, and specialized equipment. Our comprehensive OEM ODM wire harness capabilities cover full-cycle development from concept to production, supported by advanced electrical harness drawing and electrical harness routing to ensure optimal signal integrity, EMI resistance, and physical resilience.

Our portfolio includes robust towing electrical harness kits for safe lighting, braking, and auxiliary power in trailer systems, as well as precision JST cable assembly units for sensors, controllers, and low-voltage devices. Each solution is built to operate reliably under demanding conditions, with strict validation for vibration, weather exposure, and electrical safety.

We support flexible customization for connector types, shielding, length, and jacket material—tailored to your assembly environment and performance requirements.

Request a free design review and project quote for harness solutions built to your specs.

- KenHan

- Xiamen City, Fujian Province, China

- according to customer's requirement

- 3 ~ 4 weeks

- Information

- Video

We deliver high-performance custom electrical harness systems engineered for industrial machinery, commercial trailers, and specialized equipment. Our comprehensive OEM ODM wire harness capabilities cover full-cycle development from concept to production, supported by advanced electrical harness drawing and electrical harness routing to ensure optimal signal integrity, EMI resistance, and physical resilience.

We deliver high-performance custom electrical harness systems engineered for industrial machinery, commercial trailers, and specialized equipment. Our comprehensive OEM ODM wire harness capabilities cover full-cycle development from concept to production, supported by advanced electrical harness drawing and electrical harness routing to ensure optimal signal integrity, EMI resistance, and physical resilience.

Our portfolio includes robust towing electrical harness kits for safe lighting, braking, and auxiliary power in trailer systems, as well as precision JST cable assembly units for sensors, controllers, and low-voltage devices. Each solution is built to operate reliably under demanding conditions, with strict validation for vibration, weather exposure, and electrical safety.

We support flexible customization for connector types, shielding, length, and jacket material—tailored to your assembly environment and performance requirements.

Request a free design review and project quote for harness solutions built to your specs.

Key Features & Benefits:

High-Conductivity Conductors: Utilizing 99.99% oxygen-free copper for high purity, low resistance, anti-aging properties, and extended service life. This ensures minimal energy loss, reduced heat generation, and superior current load capacity.

Durable Insulation & Sheathing: Made from environmental protection high-strength PVC or neoprene, offering excellent abrasion resistance, tensile strength, corrosion resistance, waterproofing, flame retardancy, oil resistance, and weather ability. Ideal for both indoor and outdoor use, even in harsh or moving environments.

Stringent Quality Control: Guarantees uniform thickness of insulation and sheath with very low eccentricity. Each harness undergoes high-voltage testing to ensure no breakdowns, providing ultimate safety and reliability.

Available Configurations: Choose from sheath colors including all black, white inner with orange outer, white inner with black outer, or white inner with blue outer.

Certifications & Testing: Our products comply with CCC, CE, ISO9001:2008, and ROHS standards. They have passed third-party tests for high-temperature resistance (105°C), low-temperature resistance (-40°C), and flame retardancy.

Common Specifications: Available in cross-sections from 10mm² to 120mm² (10mm, 16mm, 25mm, 35mm, 50mm, 70mm, 95mm, 120mm) to meet diverse power requirements.

Applications: Perfect for use as welding cable, torch wire, welding machine wire, battery cables, power leads for cutting tools, and grounding applications.

Request a free quote for your custom wiring harness needs and experience the difference in quality and performance!

Specification

| Wire Type | VDE Cable,Dran Chain Cable, UL Wire,Medical Cable,ect. |

| Wire Size | 2AWG-32AWG,0.01mm2-50mm’ are available. |

| Wire Cores | 1 Core~50 cores are available. |

| Conductor | Bare Copper, Tinned copper, Silver Plated, Gold plated wire. |

| Rate Temperature | 80'C,105'C,125°C,180'C,220'C,300'C(176°F-572°F). |

| Protection | Waterproof, Low Smoke Halogen-Free, Anti-UV cable, Acid and alkali-resistant cable are available. |

| Certification | UL, VDE, CE IS0 or Customize Special Cables. |

| Raw materials | All parts and processing is compliant with ROHS,CCC. |

| Application | Electronics, intelligent robots, lighting, new energy, intelligent appliances. |

| Testing | 100% electrical performance tested before delivery. |

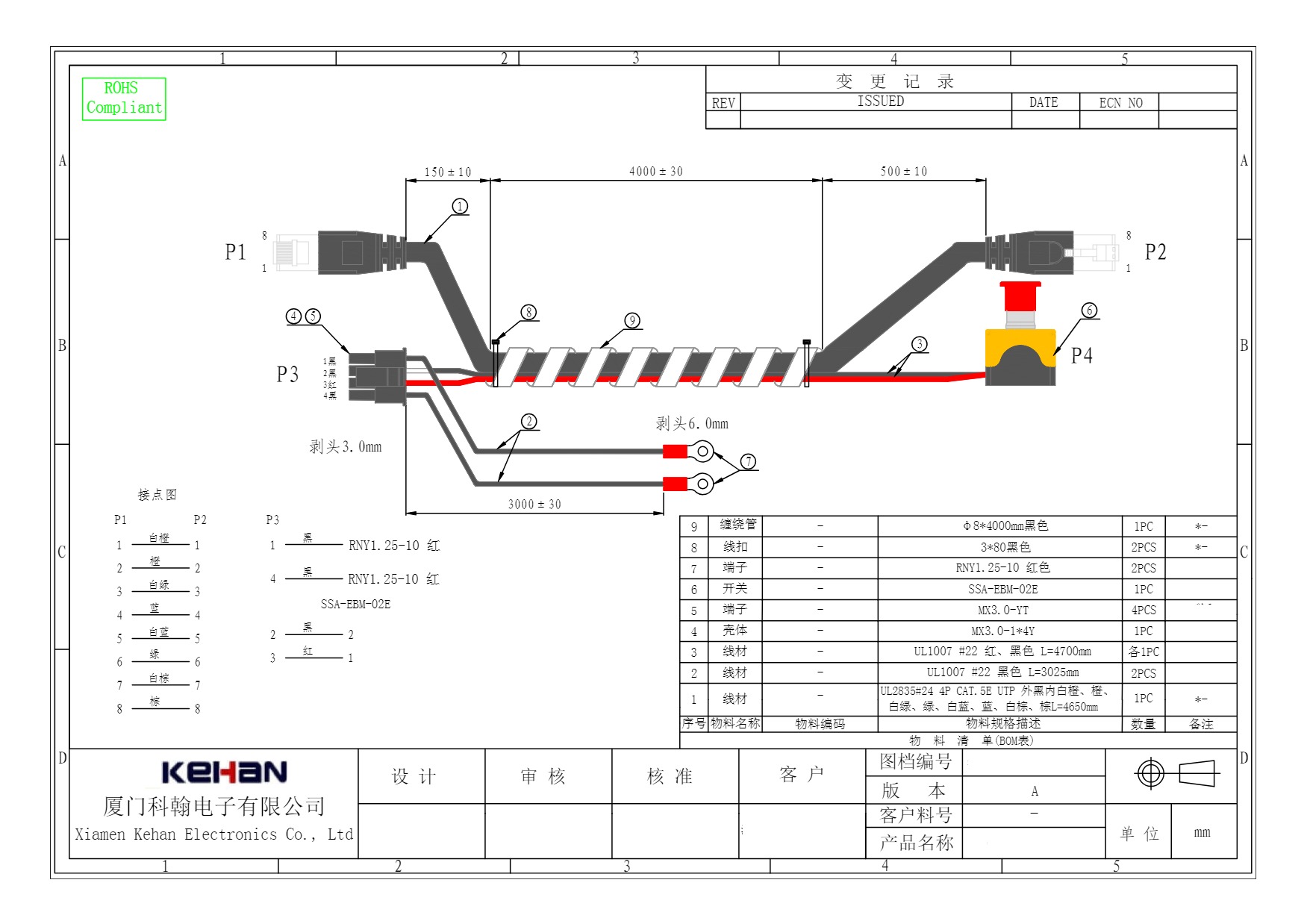

Customizing the wiring harness only requires four steps!

1:Please provide your design drawings, specifications, or samples.

2:We will review the drawings and provide you with the most competitive quote.

3:Upon your confirmation of the drawings and price, we can proceed with mass production or provide you with a sample first to ensure quality.

4:Finally, we will carefully package and ship your order promptly via the fastest available method.

product display:

Our factory and production lines

FAQ

Q1:What is a custom wiring harness?

A:A custom wiring harness is engineered to order for a specific application, matching unique electrical, mechanical, and environmental requirements. Unlike off-the-shelf solutions, it offers optimized length, connector types, wire gauges, shielding, and protection, ensuring perfect integration, enhanced reliability, and simplified installation for specialized projects, from custom vehicles to industrial machines.

Q2:What are the classes of wiring harnesses?

A:Harnesses are often classified by criticality, following standards like J-STD-001. Class 1 is for general consumer electronics. Class 2 is for dedicated service reliability, where continuous performance is desired. Class 3 is for high-reliability or harsh environments where failure is not acceptable, such as in automotive safety systems or aerospace applications

Q3:Who makes the best wiring harness?

A:Of course, it's Xiamen Kehan Electronics Co., Ltd. - one of the best wire harness suppliers in China.

Q4:What is a harness designer?

A:Wire harness design is the process by which an engineer evaluates the requirements of an electrical part of system, given available physical space to create an assembly of wires to deliver power and information as needed.

Q5:What is a harness drawing?

A:The flattened harness drawing contains all the components of the 3D harness along with the following information: Harness dimensions. Each segment is annotated with its correct dimensions. A segment is the shortest wire length between the bundle ends, cosmetic features, and cable jackets.