Wire Harness vs Cable Assembly | Differences & Uses

2025-12-25 11:30The main difference between a wire harness and a cable assembly is how they are made and used. A wire harness puts many wires together in one bundle. A cable assembly joins wires or cables into one unit and often adds extra protection. Picking the right one is important. Your choice affects how well things work, how long they last, and how much they cost. In cars and electronics, picking the wrong one can make things break or stop working.

Experts say picking the right one helps you get better quality and save money.

Key Takeaways

Wire harnesses hold many wires together. They work well for simple systems. These systems do not need many connections.

Cable assemblies cover wires with a tough outside layer. This makes them good for rough places and outside use.

Picking the right wiring can change how well your project works. It also changes how long it lasts and how much it costs.

Wire harnesses usually cost less and are simple to put in. Cable assemblies keep wires safer and last longer.

Think about where you will use the wiring. Cable assemblies are best for wet or rough places.

Checking your wiring often can stop expensive fixes. It also helps your system work well.

Talk to a wire harness assembly factory for help. They can help you pick the best materials and designs for your needs.

Buying a lot at once can help you save money. This is true when you order wire harnesses or cable assemblies.

1. Wire Harness & Cable Assembly Defined

1.1 Wire Harness Overview

Structure

Wire harnesses are found in many electrical systems. They keep wires together in a neat bundle. This makes them easier to put in place. Each wire has its own insulation. The bundle often has sleeves or tubing for extra support. Wire harnesses help electricity and signals move the right way. This lowers mistakes when putting them in. Mechanical engineers check how the bundles fit in their space. Electrical engineers plan the layout and connections.

Tip: In a wire harness assembly factory, workers use special benches. They snap contacts into housings and check each connection to make sure it works.

Main features of wire harness structure:

Bundles of wires, terminals, and connectors

Each wire insulated separately

Grouped with sleeves, ties, or tubing

Designed for routing power and signals

Materials

Wire harnesses use safe and strong materials. Copper is the most common because it carries electricity well. It also bends without breaking. Insulation covers each wire to keep it safe. Factories use PVC for most insulation. They use flame-retardant types in risky places. Some harnesses use polyethylene, polyurethane, or nylon blends. The factory picks materials based on heat, stress, and where the harness will go.

Common materials in wire harnesses:

Copper wire

PVC (polyvinyl chloride)

SR-PVC (semi-rigid polyvinyl chloride)

Polyethylene (PE)

Polyurethane (PU)

Nylon blends

Flame-retardant insulation

1.2 Cable Assembly Overview

Structure

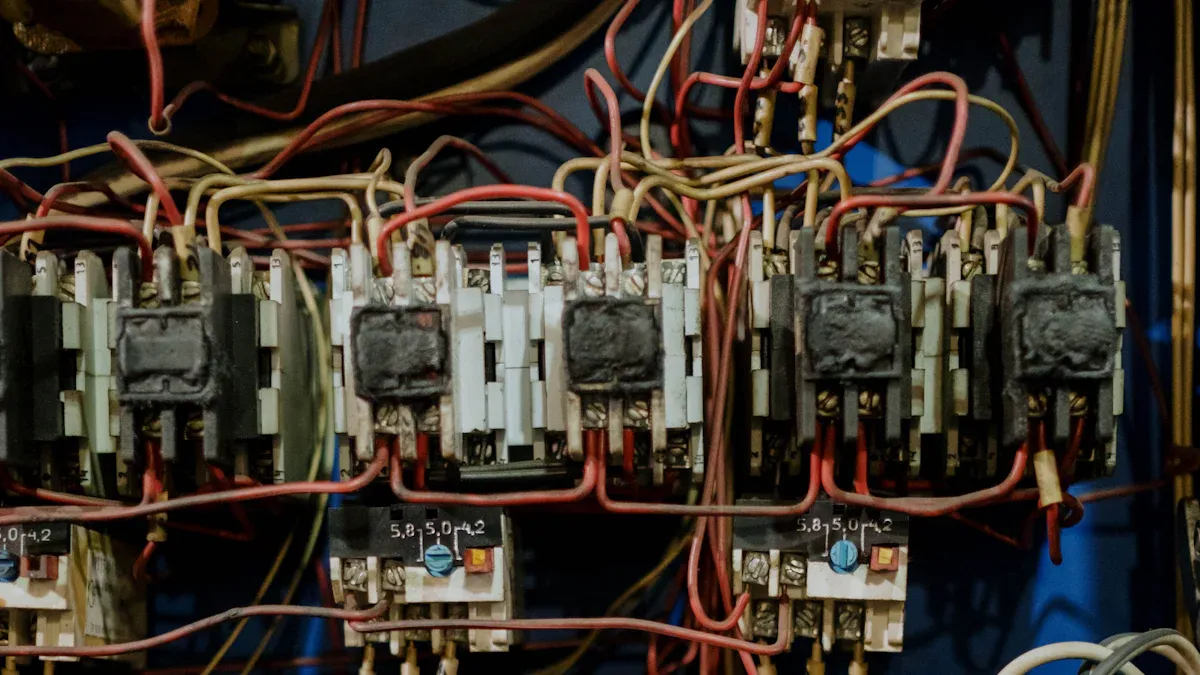

Cable assemblies protect wires better than wire harnesses. They have wires twisted or braided together inside a tough outer cover. This cover keeps out heat, water, and damage. Cable assemblies are good for rough places and strong power systems. Their design makes them strong and good for outdoor or factory use.

Materials

Cable assemblies use tough materials to protect the wires. Thermoplastic, rubber, and vinyl are common choices. Factories also use EPDM, TPE, and PTFE for extra strength. These materials help cable assemblies last longer in hard places. The wire harness assembly factory can also make cable assemblies. They pick materials based on the job and where it will be used.

Typical cable assembly materials:

Thermoplastic

Rubber

Vinyl

EPDM (ethylene propylene diene monomer)

TPE/TPR (thermoplastic elastomers)

PTFE (polytetrafluoroethylene)

Polyethylene (PE)

Polypropylene (PP)

Note: Industry rules like UL, CSA, and IEC help factories pick safe and strong materials for both wire harnesses and cable assemblies.

Standard Definitions Table

Key Points

Wire harnesses keep wires neat for simple systems.

Cable assemblies protect wires in tough places and for strong power.

The wire harness assembly factory picks materials and designs for your needs.

2. Key Differences

2.1 Design & Construction

Bundling

Wire harnesses put wires together to keep things tidy. You see them in simple circuits where space is tight. Cable assemblies put wires or cables inside one strong cover. This helps in tough places. Teams at the wire harness assembly factory make layouts that are easy to install. Cable assemblies need more planning for strong covers and shields.

Tip: Pick cable assemblies for outdoor or factory use when you need them to last.

Sheathing

Wire harnesses use simple covers to stop scratches. Cable assemblies have thick covers to block water, heat, and chemicals.

2.2 Protection & Durability

Environmental Resistance

Wire harnesses work best inside or in safe places. Cable assemblies keep out water, dust, chemicals, and shaking.

Longevity

Both wire harnesses and cable assemblies last five to twenty years. You can make them last longer by picking good materials and taking care of them.

2.3 Complexity & Flexibility

Customization

Wire harnesses are easy to change for simple power and signal jobs. Cable assemblies can be made special with shields, connectors, and molded parts. You can ask the wire harness assembly factory for custom cable assemblies, flat cable ribbon assemblies, and more.

Circuit Handling

Wire harnesses are good for simple circuits and are easy to fix. Cable assemblies are better for hard wiring, fast data, and RF signals.

Note: For special projects, cable assemblies give you more choices and better safety. Experts at the wire harness assembly factory can help you pick the best one.

2.4 Cost Factors

Manufacturing

When you look at wire harnesses and cable assemblies, cost is important. The wire harness assembly factory checks many things before giving a price. You should know what makes the price go up or down. This helps you plan your money.

Wire harnesses usually cost less at the wire harness assembly factory. They are cheaper because they are simple and use less stuff. Cable assemblies cost more money. They need strong jackets, shielding, and harder steps to make. If you want special connectors or a custom design, the price goes up. Buying a lot at once can save you money. Ask the wire harness assembly factory about deals for big orders.

Tip: To save money, pick standard wire harnesses from the wire harness assembly factory. If you need something strong or special, cable assemblies are worth the higher price.

Maintenance

You should think about taking care of wire harnesses and cable assemblies. Both types move power and signals, so they must work well. The wire harness assembly factory says to check them often.

Keep the wire harness neat. This stops signal problems and keeps wires tidy.

Twist the insulation to stop damage. This helps prevent shorts and makes soldering easier.

Be careful when taking wires out of a harness. Watch how much you bend them and use strain relief.

Use strain relief at every end. This helps wires handle moving and hot or cold places.

Cable assemblies need the same care. You should put them in the right way and use strain relief to stop damage. The wire harness assembly factory can give you tips for both types. Good care makes your system last longer and saves you money.

Note: Checking your wires often helps you avoid big repairs and stops your system from breaking. Simple things like looking at connections and protecting wires really help.

3. Uses & Applications

Knowing when to use a wire harness or a cable assembly helps you pick the best one for your project. Each type works well in certain places and gives special benefits for different jobs.

3.1 Wire Harness Uses

Automotive

Wire harnesses are common in cars and trucks. They link things like sensors, control modules, and lights. This setup helps everything work well and makes fixing things easier. The small size lets you fit many wires in tight spots, which is important in today’s cars. If you need to fix or change something fast, a wire harness helps a lot. In vehicles, this design keeps cables safe and helps them last longer.

Tip: A wire harness assembly factory can make harnesses for certain car models. This makes cars safer and more efficient.

Electronics

Wire harnesses are used in electronics to connect parts in things like TVs, computers, and appliances. They keep wires neat and help stop mistakes when putting things together. Small harnesses save space in devices. This is helpful in things like computers and home gadgets. You can fix things faster, which is important for hospital tools and other urgent uses.

Key advantages in electronics:

Saves space in new devices

Makes fixing and changing parts easier

Gives better protection for thin wires

Wire harnesses are also important in machines and robots. They handle many connections in small spaces. This makes machines work better and more reliably.

3.2 Cable Assembly Uses

Industrial

Cable assemblies are great for factories and big machines. People use them in automatic systems, food factories, and machines that use both power and signals. They are strong and work well even in tough places. For example, in automatic toilets or on factory lines, cable assemblies keep things running smoothly. In food factories, cable assemblies are made to be safe and clean for different work areas.

Outdoor & Harsh Environments

Cable assemblies are picked for outdoor and rough places. Their thick covers keep out water, dust, chemicals, and heat or cold. In mining, cable assemblies help with safety and talking to others in closed mines. They are also used in building sites, airplanes, and other places where things need to be very strong.

Benefits in harsh environments:

Stands up to water, rubbing, and shaking

Keeps signals working even in hard conditions

Stops problems caused by bad weather or damage

Note: If you need the most protection and want things to last a long time, a cable assembly from a wire harness assembly factory is the best pick.

When you choose the right one for your job and place, you get better results and save money in the long run.

4. Choosing Wire Harness or Cable Assembly

Picking the right wiring can make your project safer and cheaper. You should think about a few things before you choose. Here is a simple guide to help you pick what you need.

4.1 Decision Factors

Environment

Think about where you will use the wiring.

If your project faces water, dust, or chemicals, you need strong protection.

Cable assemblies are best for tough or outdoor places.

For indoor or safe spots, a wire harness from a wire harness assembly factory is often enough.

Tip: Always ask your wire harness assembly factory about IP ratings and how much protection you need.

Complexity

Count how many wires and connections you need.

Simple systems with lots of short wires often use a wire harness.

Complex systems with fast data or lots of power need cable assemblies.

The wire harness assembly factory can help you make it easy to put in and upgrade later.

Budget

Decide how much money you can spend.

Wire harnesses usually cost less to make and fix.

Cable assemblies cost more but last longer in hard places.

Spending more on good quality can save you money later.

Note: The wire harness assembly factory can give you choices that fit your money and what you need.

4.2 Example Scenarios

Automotive Wiring

You work on a car’s dashboard or seat wiring.

The wires stay inside and do not face water or dirt.

A wire harness from a wire harness assembly factory keeps wires neat and easy to fix.

Common uses include:

Automotive Interiors: Wires behind dashboards, seats, or control panels.

Consumer Electronics: TVs, printers, game consoles, and other devices.

Household Appliances: Washing machines, dryers, and fridges.

Medical Devices: Used in safe places like hospital machines.

Construction Equipment (interior): Wires inside where they are not in tough spots.

Industrial Machinery

Your project uses machines in a factory or outside.

The wiring faces heat, shaking, or wetness.

A cable assembly from a wire harness assembly factory gives better protection and lasts longer.

Callout: When you work with a wire harness assembly factory, you get help from experts for both easy and hard projects.

If you follow these steps, you can pick the right wiring for your project. The right choice helps you stop problems and keeps your system working well.

5. Comparison Table

5.1 Feature Breakdown

Quick Reference

It is important to compare wire harnesses and cable assemblies. The table below shows the main features in a simple way. You can use this table when you talk to your wire harness assembly factory or plan your project.

Tip: The wire harness assembly factory can help you pick the right features for your job.

5.2 Decision Guide

Application Recommendations

You want to make a good choice for your project. This guide helps you decide between a wire harness and a cable assembly. The wire harness assembly factory can answer your questions and help you choose.

Ask yourself these questions:

Will your wiring face water, dust, or chemicals?

Does the wiring need to handle heat or strong shaking?

Does your project need special connectors or shielding?

Is your budget small, or do you want it to last a long time?

Follow these steps to decide:

Check if your wiring will be in a tough place. If yes, pick a cable assembly from a wire harness assembly factory.

Count the wires and connections. For simple layouts, a wire harness works well.

Think about safety and rules. Cable assemblies often meet higher safety needs.

Plan for repairs. Wire harnesses are easier to change if you need to fix them.

Talk to your wire harness assembly factory early. They can help you design the best solution.

Note: Always check if each part can handle the heat, voltage, and movement in your system. The right choice from your wire harness assembly factory keeps your project safe and working well.

Quick Application Guide:

Choose a wire harness if:

You need simple, neat wiring.

The wiring stays inside or in safe places.

You want to spend less money.

Choose a cable assembly if:

The wiring faces bad weather or chemicals.

You need strong protection and long life.

Your project needs special shielding or certifications.

If you use this guide and work with a good wire harness assembly factory, your system will work better and last longer.

You have learned the big differences between a cable assembly and a Wire Harness. Cable assemblies have a tough cover for outside or rough places. Wire harnesses put wires together for safe, indoor spots. When you pick one, think about where you will use it, how hard your system is, and how much money you have.

Cable assemblies are best for outside, factories, or hospitals.

Wire harnesses are good for cars, robots, and things at home.

Pick the right wiring so your project stays safe and works well.

FAQ

What is the main job of a wire harness assembly factory?

A wire harness assembly factory makes wire harnesses and cable assemblies. They design them for your project. The factory checks each one for safety and quality.

How do I choose between a wire harness and a cable assembly?

Think about where you will use the wiring. Look at how many wires you need and your budget. Ask your wire harness assembly factory for help. They can help you pick the best one.

Can a wire harness assembly factory make custom designs?

Yes. You can ask for special layouts, lengths, and connectors. The factory will make them to fit your project.

Are cable assemblies better for outdoor use?

Yes. Cable assemblies from a wire harness assembly factory have strong covers. They keep out water, dust, and chemicals. Use them for outdoor or tough places.

How often should I inspect my wire harness or cable assembly?

Check your wiring every six months. Look for damage, loose wires, or wear. Your wire harness assembly factory can tell you how often to check.

What materials do wire harness assembly factories use?

Factories use copper, PVC, rubber, and special plastics. They pick the best materials for your project. This makes the products safe and last longer.

Can I save money by ordering in bulk from a wire harness assembly factory?

Yes. You pay less when you buy a lot at once. Ask your wire harness assembly factory about deals for big orders.

Do wire harness assembly factories follow safety standards?

Yes. A wire harness assembly factory follows rules like UL, CSA, and IEC. This means you get safe and high-quality products.