The Complete Wire Harness Manufacturing Process Explained

2025-12-17 11:22You want each step in Wire Harness Manufacturing to work well. Customer design files and special software help make things exact and fast. When you use machines to do jobs, you save a lot of time. The table below shows how digital tools and machines help make work better and faster. Top companies like Xiamen Kehan Electronics use these smart ways to get great results.

Key Takeaways

Begin with a solid design to make wire harnesses reliable. Use smart tools to find errors early.

Pick the best materials for wires, connectors, and insulation. Good materials help harnesses last longer and stay safe.

Organize your workspace to work better. A clean area helps you work quickly and make fewer mistakes.

Use machines to cut, strip, and crimp wires. Machines help you be more exact and save time.

Test each harness carefully before sending it out. Check with electrical tests and look closely to make sure it is safe and good quality.

Pack wire harnesses well so they do not get damaged when shipped. Strong packaging keeps them safe and ready to use.

Follow rules like IPC/WHMA-A-620 for quality checks. These rules help keep safety and reliability high.

Pick a certified maker like Xiamen Kehan Electronics for good results. Certifications show they care about quality and safety.

1. Wire Harness Manufacturing Design

The Wire Harness Manufacturing process starts with a strong design step. This step is important for making good and reliable products. Companies like Xiamen Kehan Electronics use advanced tools and careful checks. They make sure every harness fits what you need.

Customer Design Review

Specification Check

You look at all customer files and specifications first.

You check for mistakes like wrong measurements or wire sizes. These mistakes can make wires too hot or not fit right.

You look for problems in making, like bad wire layout or wrong machine settings.

You stop bad quality by picking good materials and making sure over-molding is done right.

Application Needs

You think about what each harness needs for its job. Some harnesses must work in hard places or small spaces.

You make sure the design is safe and works well by following industry standards.

Sometimes you need special solutions, so you do extra tests and get certifications.

You use wire lists and drawings to make each harness fit its job.

Schematic And Simulation

Signal Integrity

You care about signal integrity to stop data loss or noise.

You use simulation tools to test signals in the harness before making it.

Simulation Tools

Tip: The right software helps you work faster and make fewer mistakes.

Digital tools help you design faster.

You make fewer mistakes and work better with your team.

You save time and money and make a better harness.

Software Layouts

2D/3D Design

You use 2D and 3D design software for accurate layouts.

A 3D digital twin lets you see and fix wire paths before making them.

File Sharing

You share design files with your team and customers for feedback.

You use catalogues so everyone has the same information.

You check your design with rules to find mistakes early.

Xiamen Kehan Electronics is a top wire harness manufacturer because they use these smart steps. You can trust their design and simulation process to give you good results every time.

2. Material Selection And Preparation

Picking the right materials is very important in Wire Harness Manufacturing. You need to choose wires, cables, connectors, and terminals that follow strict rules. Good materials help stop problems and make the harness last longer. Xiamen Kehan Electronics is a good example because they use top material standards.

Wire And Cable Choice

First, you pick wires and cables that fit your project. Think about these things:

Electrical Load Requirements: Make sure the wire can handle the power without getting too hot.

Material Choices: Copper and aluminum are used a lot. Copper lets electricity flow better. Aluminum is lighter and costs less.

Insulation Options: PVC, Teflon, and silicone keep wires safe from heat, water, and chemicals.

Connector Types: Pick connectors that work with your system. Use waterproof ones if you need them.

Regulatory Standards: Check that your materials meet UL, CE, or RoHS safety rules.

Gauge And Insulation

Wire gauge tells you how much current the wire can carry. Thicker wires carry more current and do not get hot as fast. Insulation keeps wires safe from tough places. Pick insulation that fits the heat and chemicals your harness will face.

Quality Standards

Good wire harnesses follow strong quality rules. The IPC/WHMA-A-620 standard helps you pick and test wires and cables. This rule helps you find good products and makes sure your harness passes tests. Certified makers like Xiamen Kehan Electronics use these rules for safety and trust.

Connector And Terminal Selection

Connectors and terminals join wires and make safe paths for electricity. You should think about a few things when picking them:

Current Rating: Choose terminals that can handle the needed power.

Environmental Resilience: Make sure terminals can handle heat, water, shaking, and chemicals.

Material Composition: Copper, aluminum, nickel-plated, and gold-plated terminals last different times and work in different ways.

Types And Materials

There are many kinds of terminals, like ring, spade, bullet, and butt connectors. Each kind has its own job. The material and shape change how well the terminal works in hard places.

Performance Needs

You need to match the connector and terminal to the wire size and where it will be used. Waterproof connectors are best for wet places. High-temperature terminals are good for hot spots.

Cutting And Labeling

After you pick your materials, you get them ready to use.

Precision Cutting

Machines cut wires to the right length. Cutting them right stops waste and makes sure each wire fits well.

Labeling Systems

Labels help you keep track of each wire. You can use printed labels, colors, or barcodes. Good labels help stop mistakes and make fixing things easier.

Tip: Always check your materials and labels before you move on. This helps you stop mistakes and keeps Wire Harness Manufacturing running smoothly.

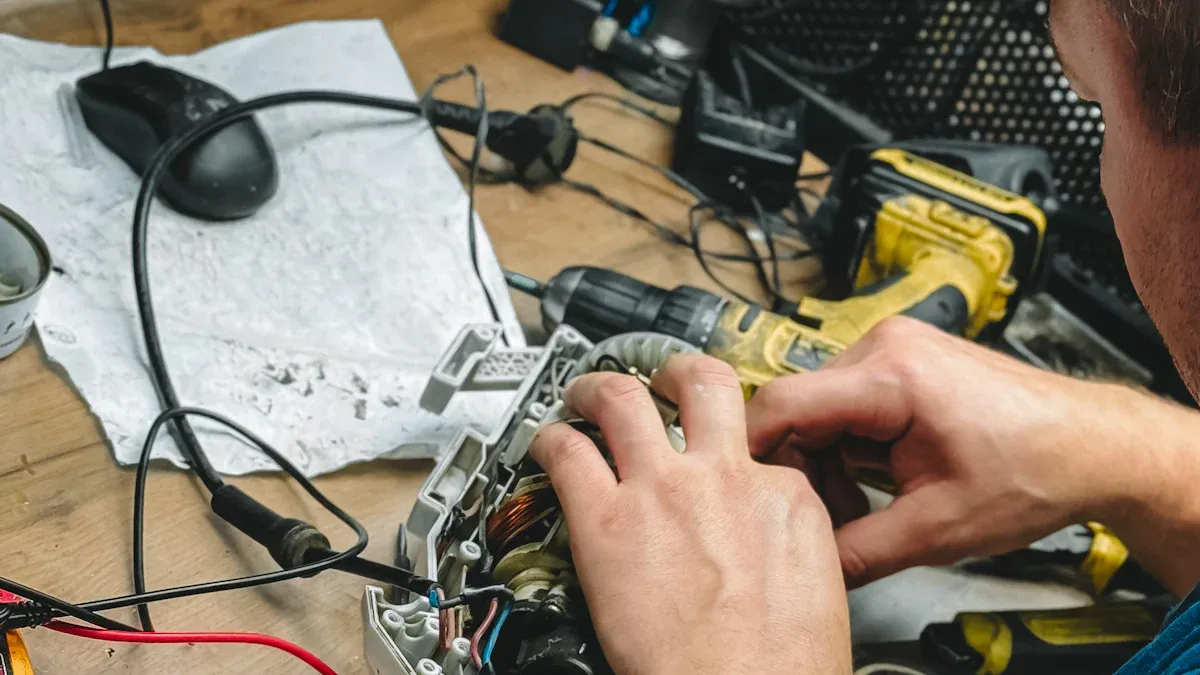

3. Assembly Board And Process Setup

Getting your assembly board ready is very important. You need a good workspace to work fast and stay neat. This helps you keep your work high quality. The best wire harness makers use these steps. They make sure every harness is made the right way.

Board Layout

A smart board layout helps you make fewer mistakes. First, plan where each wire and connector will go.

Pin Placement

Put pins on the board to match your plan.

Label each pin clearly so you do not get mixed up.

Make sure each pin fits the right wire and connector.

Fixture Setup

Use fixtures to hold wires and connectors in place.

Pick fixtures that can change size for different harnesses.

Check that fixtures are tight so nothing moves while you work.

Component Staging

Getting your parts ready before you start saves time. It also helps you make fewer mistakes. Group wires, connectors, and terminals so you can find them fast.

Organization

Sort wires by color, length, and type.

Put connectors and terminals in bins with labels.

Lay out your parts in the order you will use them.

Tool Prep

Get all your tools ready before you start.

Make sure crimpers, cutters, and testers work well.

Keep tools close by so you can grab them quickly.

If you set up your parts well, you can work up to five times faster. You make fewer mistakes and your work is better. Using adjustable setups helps both ends of the cable pinning.

Workstation Setup

How you set up your workstation changes how well you work. It also helps you stay safe. Make your space comfy so you do not get hurt.

Ergonomics

Use workstations that can change height and angle.

Pick tools that fit your hands and are easy to use.

Set up your space to stop awkward moves and hard work.

Safety

Check your area often to find and fix dangers.

Use good setups to help stop injuries.

Teach everyone how to use machines safely and what to do in emergencies.

Tip: A neat and safe workstation helps you work faster and safer. You make fewer mistakes and avoid getting hurt. This keeps your work going well.

If you follow these steps, you set up your board and process for success. You make a safe, fast, and high-quality place to build wire harnesses every time.

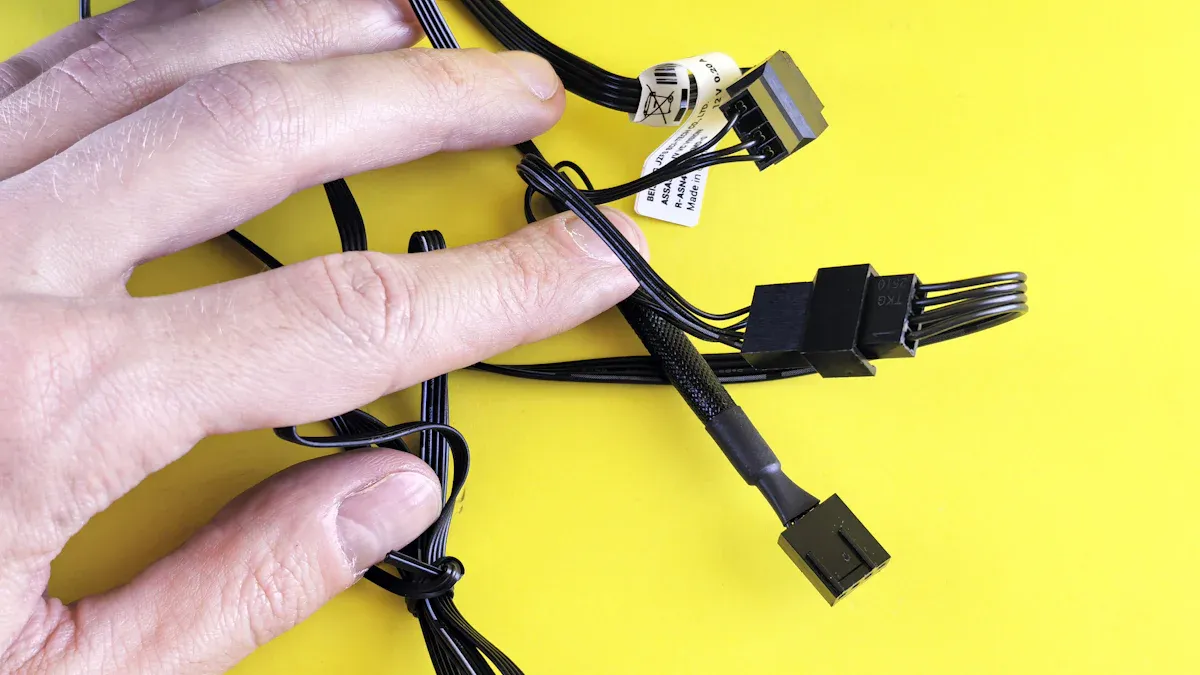

4. Wire Cutting, Stripping, Crimping, And Injection Molding

At this stage, you turn materials into wire harnesses. Each step helps make the harness strong and last longer. Top companies like Xiamen Kehan Electronics use smart machines and careful checks to get great results.

Wire Cutting Accuracy

Machine Cutting

First, you cut wires to the right length. Machines do this job fast and very accurately. They can cut hundreds or thousands of wires every hour. This saves time and stops mistakes that happen when people cut by hand. Machines also make sure every wire is the same.

Machines help you work faster and make fewer errors. You lower the chance of hurting the wires and finish more work. Your team can spend time on harder jobs.

Length Verification

After cutting, you check each wire’s length. You use rulers or machines to make sure the wires are correct. This step helps you find mistakes early. If you fix problems now, you save time and materials later.

Stripping And Crimping

Terminal Attachment

Next, you remove the insulation from the ends of the wires. Machines do this quickly and keep the wire safe. Then, you use crimping tools to attach terminals. Crimping connects the terminal to the wire so electricity can flow.

Machines make stripping and crimping faster.

You get good results and do not damage the wire.

Quality Checks

You check each crimp to make sure it is strong:

Look at crimps to see if they are tight and neat.

Pull and test the wires to check strength and electrical flow.

Make sure no wire strands stick out of the crimp.

Check that the insulation is still good near the terminal.

Pull on the connection to see if it holds.

Measure resistance to make sure electricity flows well.

These checks help you stop weak spots that could break later.

Injection Molding

Sealing Connections

You use injection molding to cover and protect the connections. Overmolding makes a seal that keeps out water, chemicals, dust, and scratches. This step is important for harnesses used in tough places.

Plastic Overmold

Low-pressure injection molding adds more protection. It makes the connection points stronger and stops damage from pulling or bending. You also get better protection from chemicals, heat, and bending. The process covers the wires and keeps them safe from dirt and stress.

Overmolding helps your wire harnesses last longer.

You protect your harnesses from hard conditions and make them work longer.

Xiamen Kehan Electronics uses careful steps at every part. You can trust their ways to make strong and safe wire harnesses for any job.

5. Assembly, Testing, And Shipping

Wire Bundling

Wire bundling is an important step in Wire Harness Manufacturing. You need to keep wires organized so they stay safe and work well.

Routing Patterns

You plan wire paths to avoid sharp bends. You look for the shortest and safest way for each wire. You think about how wires will move or bend when used. You pick cables with the right flexibility, insulation, and shielding.

Fine-strand conductors and torsion-rated cables are good for moving parts.

You plan wire routes to stop pulling, twisting, or shaking.

You look at different ways to route wires for the best design.

Bundling Methods

You use different ways to bundle wires depending on the job. You might use zip ties, lacing, or sleeves to hold wires together. You also use braided shields, foil wraps, or ferrite parts to block electromagnetic interference (EMI/RFI). In tough places, you add grommets, over-molding, or sealed connectors to keep out water and dust.

Using conduits can protect cables by putting them inside a tube. Metal conduits are very good at blocking EMI/RFI.

Securing Components

You need to keep all parts in the harness from moving or getting damaged.

Cable Ties

You use cable ties to hold wires together. You put ties at regular spots to keep bundles neat. You do not pull ties too tight so wires do not get hurt. You might use jigs and fixtures to keep wires in place while you work. Temporary holders help keep wires in order for every harness you make.

Bundle wires with zip ties or electrical tape.

Use jigs and fixtures to put wires in the right place.

Use heat-shrink tubing to protect soldered joints.

Protective Sleeves

You add sleeves to protect wires from rubbing and heat. You pick sleeves made from nylon or silicone for the right place. You make sure sleeves fit well but do not squeeze wires. You use heat-shrink tubing for extra safety at connection points.

Testing And Quality Control

Testing makes sure your harness works safely and well.

Electrical Testing

You test wires to check if they are connected right and the insulation is good. You use continuity tests to see if each wire connects like it should. You use Hi-Pot tests to check insulation by using high voltage.

Electrical testing helps you find broken wires and insulation problems before you ship.

Visual Inspection

You look at each harness to find any problems. You check for loose or broken connectors, rubbing, or worn insulation. You look for wrong wiring, rust, and bad strain relief. You make sure wires are not bent wrong, crimps are at the right height, and insulation covers the wire past the crimp tab.

You fix problems by redoing connections, changing bad wires, or making strain relief better. Careful checking helps you send out wire harnesses you can trust every time.

Packaging And Shipping

A wire harness manufacturer must keep every product safe when shipping. You want your wire harnesses to arrive without damage and ready to use. Packaging and shipping are important for keeping wires safe and making sure you get good products.

Protective Packaging

You need strong packaging to stop wire harnesses from getting hurt. Good packaging keeps out heat, shaking, and water. It also keeps wires neat and easy to handle. The best wire harness makers use many ways to protect their products:

Use packaging you can use again to save money. You can use these boxes many times, which helps your wallet.

Pick packaging that is better for the earth. Reusable boxes help the planet by making less trash.

Choose packaging that stops wires from making noise. This is important for car wire harnesses, where quiet is needed.

Use materials that keep wires safe from heat, shaking, and water. This keeps your harnesses safe when moving or storing them.

Keep wires neat inside the box. This makes it easier to put in and fix later.

Use boxes that fold up to save space when shipping. These boxes help you ship more at once.

Stackable and small boxes help you store more harnesses in less space. This helps your business.

Use packaging that lasts for many trips to make less trash. You help the earth by not throwing away boxes after one use.

Tip: When you work with a wire harness maker like Xiamen Kehan Electronics, you get smart packaging that keeps your products safe and helps the planet.

Logistics

Logistics plans help you get wire harnesses fast and in good shape. A wire harness maker must plan making and shipping to fit your needs. Good production steps, like line balancing, help stop slowdowns and keep up with orders. You want your wire harnesses to come fast and without damage.

Careful planning between making and shipping makes sure every harness gets to you in great shape. Wire harnesses are tricky, so you need good planning at every step. A wire harness maker uses smart shipping to get products to you when you need them, so your projects stay on track.

Plan shipments to fit your project schedule.

Track orders so you always know where your wire harnesses are.

Use good shipping companies to stop damage while moving.

Talk with you about when your order will come and any changes.

Note: Xiamen Kehan Electronics is a top wire harness maker because they use good shipping plans and strong packaging. You get products that come safe, on time, and ready to use.

You are important in every part of Wire Harness Manufacturing. Each step, from design to shipping, helps make good products. Using strong wires, connectors that do not rust, and tough insulation helps stop problems. These good habits help you:

Pick the right materials so things last longer.

Test everything carefully to make sure it works well.

Use rules like IPC/WHMA-A-620 to keep quality high.

Quality control helps you find and fix mistakes before customers get the product. This makes failures less likely.

Xiamen Kehan Electronics is special because they use smart tools, follow certified steps, and have a skilled team. Their certifications show how they are different:

You can use these ideas for your own projects or when picking a supplier to get better results.

FAQ

1. What does a wire harness manufacturer do?

A wire harness manufacturer makes, puts together, and checks wire harnesses for electrical systems. These products join wires, cables, and connectors. They help send power or signals safely and reliably.

2. How do you choose the right wire harness manufacturer?

Check if the manufacturer has certifications and uses good materials. Make sure they can make enough products for your needs. Look for strong quality checks, quick delivery, and experience in your field.

3. Why is material selection important in wire harness manufacturing?

Picking the right materials helps the harness last longer and stay safe. Good wires, connectors, and insulation make the harness work well for your project.

4. What quality standards should a wire harness manufacturer follow?

Expect standards like IPC/WHMA-A-620, ISO 9001, and UL certification. These rules help make sure your wire harnesses are safe and reliable.

5. How does a wire harness manufacturer test products before shipping?

Manufacturers use electrical tests, look at the harnesses, and check resistance. Harnesses must pass tests for connections, insulation, and strength before you get them.

6. Can a wire harness manufacturer customize products for special applications?

Yes, you can ask for special designs, materials, or connectors. The manufacturer will look at what you need and make harnesses that fit your project.

7. What packaging methods does a wire harness manufacturer use?

You get harnesses in strong packaging like reusable boxes, anti-static bags, or foam inserts. These keep products safe while shipping and storing.

8. How do you contact a wire harness manufacturer for support?

You can contact them by email, phone, or online forms. Most manufacturers give technical help, price quotes, and order tracking for your project.