In-Depth Technical Analysis of Wire Harness Crimping: Core Processes for Tubular Terminals and Shield Rings

2026-01-08 15:52In-Depth Technical Analysis of Wire Harness Crimping: Core Processes for Tubular Terminals and Shield Rings

Terminals serve as the critical components within wire harnesses, enabling electrical connections and transmitting current and signals. The quality of their crimp joints directly determines the harness's overall reliability, durability, and safety. Based on structural design, terminals are primarily classified into two categories: open-barrel (or open-style) and closed-barrel (tubular). Open-barrel terminals are predominantly used in conventional low-voltage harnesses, where the crimping process is well-established and mature. In contrast, closed-barrel terminals, benefiting from their fully enclosed structure which provides superior mechanical strength, enhanced sealing, and improved vibration resistance, have become the mainstream choice for high-voltage harnesses in new energy vehicles. Concurrently, to meet the stringent electromagnetic compatibility (EMC) requirements of high-voltage systems, the crimping of shield rings has also emerged as an essential manufacturing process for high-voltage harnesses. This article aims to provide a detailed examination of the predominant crimping methods for tubular terminals and shield rings in high-voltage harnesses, offering professional guidance for process selection and quality control.

I. Detailed Explanation of Closed-Barrel (Tubular) Terminal Crimping Methods

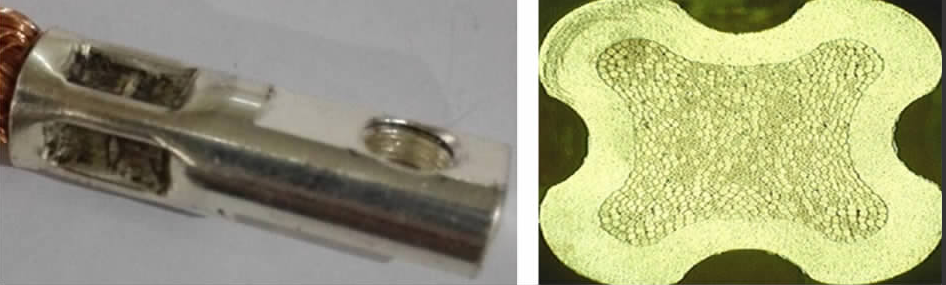

The crimping of tubular terminals aims to create a permanent, robust, and electrically optimal connection between the terminal barrel wall and the wire strands through controlled plastic deformation. The core evaluation criteria for such crimps include cross-sectional analysis (assessing strand deformation fill ratio, burr height, crimp width, etc.) and mechanical pull-force testing.

1. Hexagonal Crimping

Principle & Application: This method applies uniform pressure from six radial directions via a precision die, causing the circular terminal barrel to contract evenly around the conductor. It is primarily suitable for large-cross-section conductors of 8 mm² and above, requiring an excellent match between the conductor's cross-sectional area and the terminal's inner diameter.

Process Key Points: The crimping action must be uniform and controlled, typically executed using hydraulic equipment to prevent micro-cracks in the terminal barrel caused by instantaneous excessive stress. Prototype development often utilizes quick-change hexagonal hydraulic presses, while mass production employs specialized automated hydraulic crimping machines. The resulting cross-section is a regular hexagon with excellent strand fill and a large effective conductive area.

Advantages: Uniform stress distribution, high mechanical strength at the connection point, low electrical resistance, and optimal long-term reliability.

2. Hexagonal Two-Point Crimping

Principle & Application: This method builds upon the hexagonal crimp by adding two additional, deeper pressure points in the central region of the crimp zone. It is designed for conductors of 8 mm² and above where the conductor cross-sectional area is slightly smaller than the terminal's inner diameter.

Process Key Points: The two central pressure points induce greater localized deformation, ensuring intimate contact between the strands and the terminal wall even in the presence of minor gaps. This process demands high precision and stability from the crimping equipment, where imported high-end machines often provide an advantage. Currently, due to the ongoing refinement of national standards for high-voltage harnesses, this method is widely adopted for its excellent adaptability.

Advantages: Higher tolerance for mating tolerances between wire and terminal, providing stable electrical contact performance while maintaining required pull-force strength.

3. MW-Type Crimping

Principle & Application: An optimized variant of the hexagonal two-point crimp, where the final crimped form resembles a combination of the letters "M" and "W". It is applied to conductors of 8 mm² and above with a cross-sectional area slightly less than the terminal's inner diameter.

Process Key Points: MW-type crimping utilizes a unique die design to promote more favorable metal flow. It achieves a high-strength crimp while better controlling terminal deformation and minimizing areas of excessive work hardening. The cross-sectional quality is superior, with uniform strand embedding. This advanced process is highly regarded for high-voltage, large-cross-section terminal crimping and is supported by relevant patents.

Advantages: Combines high mechanical strength with outstanding electrical connection properties, representing an optimal solution that balances reliability and manufacturability.

4. Four-Point Crimping

Principle & Application: Compression is applied from four perpendicular directions. This method is typically used for small to medium cross-section conductors of 6 mm² and below, where the wire and terminal have a good fit.

Process Key Points: Commonly employed for 3 mm², 4 mm², and 6 mm² wire connections. The wire must be inserted into the terminal before crimping, and care must be taken to prevent the terminal from dislodging during handling. The equipment is relatively standard and offers high efficiency.

Advantages: A simple, mature, and cost-effective process, providing a reliable and economical solution for small-cross-section wires.

II. Detailed Explanation of Shield Ring Crimping Methods

The objective of shield ring crimping is to establish a low-resistance, high-strength electrical connection between the cable's braided shield layer and the connector housing, thereby creating a continuous electromagnetic shielding path. The core performance metrics are the pull-force resistance of the shield layer connection and its electrical resistance.

1. Shield Layer Hexagonal Crimping

Principle & Application: This involves the uniform hexagonal compression of the shield ring, causing it to tightly clamp the internal braided shield layer and cable core. It is suitable for conductors above 3 mm² in scenarios where the shield layer, insulation, and shield ring inner diameter fit tightly with minimal gap.

Process Key Points: The crimping force must be precisely controlled to ensure the shield layer is securely compacted without being severed. This is the most fundamental and widely used shield ring crimping method.

Advantages: Provides a uniform and reliable connection with good process stability.

2. Shield Layer Hexagonal Two-Point Crimping

Principle & Application: This method adds two central pressure points to the standard hexagonal crimp. It is primarily used for conductors above 8 mm², or when a slightly larger gap exists between the shield layer, insulation, and the shield ring inner diameter.

Process Key Points: The additional pressure points effectively compensate for gaps, ensuring that loose or thick shield layers are adequately compressed. The number and arrangement of these points require optimization based on the shield ring's length and specific design.

Advantages: Offers greater adaptability to component fit variations and can effectively handle more complex shield layer configurations.

3. Shield Layer Six-Point Crimping

Principle & Application: This technique employs six independent, discrete pressure points for crimping. It is typically used for large-cross-section cables of 10 mm² and above, or in cases of significant component gap or mismatch.

Process Key Points: This method places extremely high demands on the toughness of the shield ring material. The discrete pressure points create areas of uneven stress concentration. If the material is overly brittle, cracks can easily initiate at the pressure point edges or between points, leading to shielding failure. Strict material selection and crack inspection protocols are essential during process development.

Advantages: Provides a viable high-strength connection solution for mismatched components but requires extremely stringent control over materials and process parameters.

III. Summary and Future Outlook

In high-voltage wire harness production, terminal and shield ring crimping are defined as Critical Process Characteristics. Their quality is directly linked to the safety and performance of the vehicle's entire electrical system. During practical process development, crimping engineers must undertake a systematic analysis:

Compatibility Analysis: Conduct an in-depth study of the connector terminal/shield ring structure, materials (e.g., copper alloy grade, plating type), and their compatibility with the specified wire (cross-section, strand lay, shield density).

Custom Mold Development: Based on the analysis findings, provide precise technical specifications to mold suppliers. These should include the crimp type, target cross-sectional dimensions, key dimensional tolerances, etc., rather than仅仅提供样品 (simply providing physical samples).

Process Validation and Monitoring: Comprehensively validate crimp quality through cross-sectional analysis, mechanical performance testing (pull-force), electrical performance testing (voltage drop/contact resistance), and necessary environmental endurance tests (vibration, thermal humidity cycling). Strict Statistical Process Control (SPC) must be implemented during mass production.

Looking forward, as high-voltage platform operating voltages increase and current loads grow, demands on the current-carrying capacity, fretting corrosion resistance, and long-term reliability of crimped connections will rise further. Novel joining technologies such as ultrasonic welding and laser welding may complement traditional crimping processes. Simultaneously, digital quality control methods, including machine vision-based online real-time cross-section inspection and crimp process force-displacement curve monitoring, are poised to become core technological trends for ensuring fail-safe connections in high-voltage harnesses. Ultimately, the selection of a crimping method should be based on a comprehensive evaluation of product requirements, cost, production capacity, and quality risks, with the fundamental goal of achieving the optimal balance of electrical performance, mechanical strength, and long-term reliability.