Guide to Different Types of Wire Harnesses

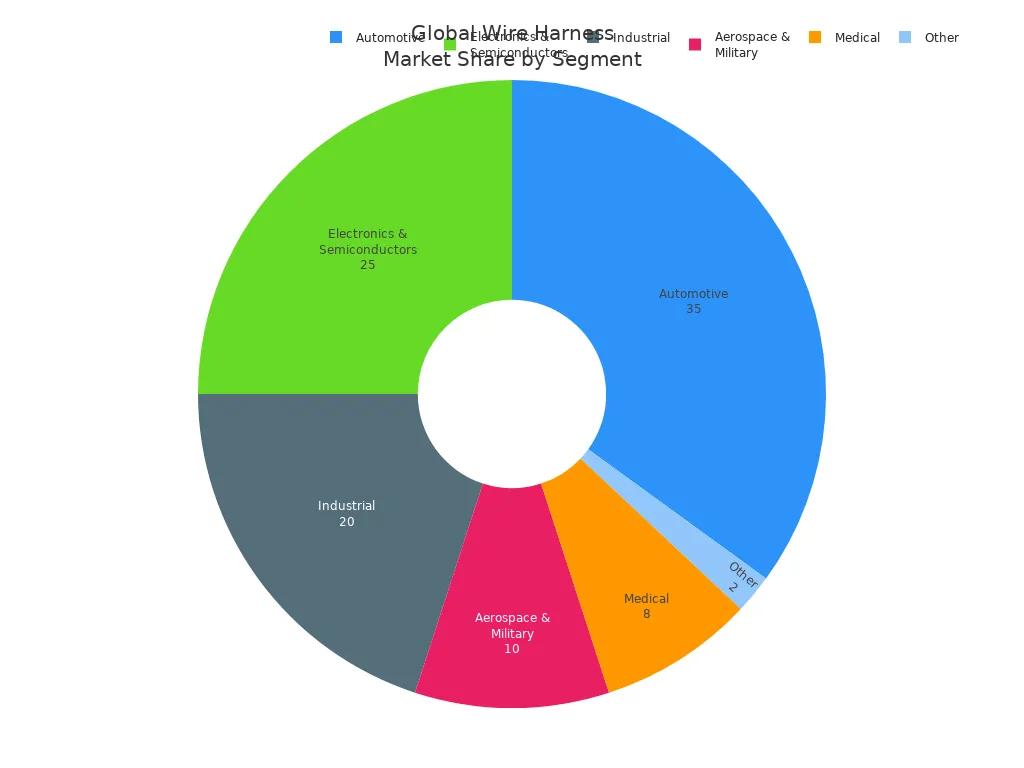

2025-12-04 11:01You will find five main types of wire harnesses. These are automotive, industrial, aerospace, medical, and custom or specialty. A wire harness keeps many wires together and safe. It sends power or data between parts. It also protects wires from water and damage. This makes things safer and less messy. It also helps electrical systems work better and last longer.

You can trust Xiamen Kehan Electronics, a leading Cable Harnesses manufacturer, to help you pick the right cable harnesses. They are experts and can give you good advice.

Key Takeaways

There are five main types of wire harnesses: automotive, industrial, aerospace, medical, and custom. Each type has a special job in different industries.

Automotive wire harnesses help connect car systems. They keep cars safe and help them work better. Pick harnesses with strong insulation and tough connectors.

Industrial wire harnesses need to handle tough places like dust, oil, and heat. Use strong materials so they last long in factories and power plants.

Aerospace wire harnesses need to be light and not catch fire. They must work in very hard conditions. Make sure they meet FAA and AS9100 safety rules.

Medical wire harnesses must follow strict safety rules. They should be easy to clean and stop electrical dangers. This keeps patients safe.

Custom wire harnesses can be made for special projects. They help save time and money by stopping mistakes and lessening downtime.

When picking a wire harness maker, look at their experience, certifications, and if they can make custom products. Xiamen Kehan Electronics is a good choice.

Always check what your project needs, like the environment and electrical needs. This helps you pick the best wire harness for good performance.

1. Automotive Wire Harnesses

Overview

Almost every car has automotive wire harnesses. These harnesses keep wires neat and safe. This helps your car work well. The main parts are wires, insulation, sheaths, and connectors. Most wires are copper because it works well and bends easily. Some harnesses use aluminum to make them lighter. Insulation, made from PVC or XLPE, stops short circuits and keeps things safe. The sheath, often PVC or TPU, protects wires from heat, water, and scratches. Connectors join the harness to car systems. They use gold or silver on contacts for better work. Terminals, made from brass or copper, help move electricity between parts.

Tip: Pick a wire harness with strong insulation and tough connectors. These help keep your car safe and working well.

Key Features

Automotive wire harnesses group many circuits for different jobs. They send power and signals to important car systems. These harnesses work like a nervous system. They connect sensors, ECUs, and other devices. They help with things like safety, comfort, and fun in your car.

A good Cable Harnesses manufacturer makes harnesses that meet high standards. This makes sure your car’s electrical parts work right.

Applications

Automotive wire harnesses do many jobs in cars today. They are in electric cars to handle battery power and charging. Smart cars use special harnesses for updates and remote checks. Lighter harnesses, often with aluminum, help save fuel and are better for the planet.

Electric cars need strong wires for safe power use.

Smart cars use harnesses for updates and checks.

Light and green harnesses use new materials to work better and waste less.

You should work with a trusted wire harness manufacturer like Xiamen Kehan Electronics. Their knowledge helps you pick the best harness for your car.

Subtypes

Automotive wire harnesses have different subtypes. Each subtype does a special job in your car. The table below shows the main subtypes and what they do:

Engine Bay Harness

The engine bay harness sits under the hood. It links the ECU to engine parts. This harness controls fuel, ignition, and sensors. It faces heat and shaking. The harness must be strong to keep the engine working.

Dashboard Harness

The dashboard harness connects dashboard buttons to the car. It links gauges, warning lights, and music systems. This harness helps you see car info while driving. It also lets you use music and maps.

Body Harness

The body harness goes through the car’s main body. It links things like power windows and seat controls. It also connects inside lights. This harness makes your ride comfy and easy. It also helps with safety, like airbags.

Door Harness

The door harness is inside each car door. It links power locks, window switches, and mirrors. This harness bends every time you open the door. Good Cable Harnesses makers build door harnesses to last a long time.

Lighting Harness

The lighting harness links all the car’s lights. It powers headlights, taillights, and turn signals. This harness helps you see and be seen on the road. Good lighting harnesses use strong materials to block rain and dust.

Tip: Each harness subtype has its own problems. Engine bay and lighting harnesses need extra protection from heat and water. Door harnesses must bend a lot. Always pick harnesses that fit your car’s needs.

2. Industrial Wire Harnesses

Overview

Industrial wire harnesses are very important in factories and hospitals. They are also used in power plants. These harnesses are found where machines work hard. The conditions in these places can be rough. They keep wires safe from dust, oil, heat, and shaking. You need harnesses that last a long time and work well in tough places. These harnesses have thick wires and strong covers to stop damage. You can trust a good Cable Harnesses maker to give you harnesses for these hard jobs.

Note: Industrial wire harnesses face more stress than automotive harnesses. You should pick harnesses made for your own work area.

Key Features

Industrial wire harnesses are strong and last a long time. You need harnesses that can handle dust, oil, and heat. These harnesses use thick wires and tough covers. They keep working for years, even when machines run all day. Some harnesses have extra shields against shaking and wetness. The design makes safety and dependability a top goal.

Tip: Always look at the materials and design before buying. Strong covers and thick wires help harnesses last longer and keep you safer.

Applications

Industrial wire harnesses are used in many places. Here are some common uses: Manufacturing lines use harnesses to link power and signals. Communication systems use harnesses to connect routers and devices. In cars, harnesses join electrical parts for power and signals. Medical equipment uses strong harnesses to keep working safely. Military systems use harnesses that follow strict rules for control and communication.

Industrial wire harnesses help machines work together. You need harnesses that fit your machines and keep them safe. A trusted Cable Harnesses maker can help you pick the right harness for your factory or plant.

Reminder: If you want harnesses that last and keep your machines working, choose a maker who knows your industry.

Voltage Types

Industrial wire harnesses can be high-voltage or low-voltage. You need to know which one your equipment needs. This helps you pick the right harness.

High-Voltage Harness

High-voltage harnesses move a lot of power. You see them in big machines and robots. They use special insulation to stop problems. Shielding keeps the wires safe from harm. These harnesses are waterproof and dustproof. Their design is simple and focuses on safety. Shielding rings protect the wires all around.

Tip: Always look at insulation and shielding before you buy a high-voltage harness. This keeps your machines safe and working well.

Low-Voltage Harness

Low-voltage harnesses move power and signals for lights and sensors. You find them in factories and communication systems. They have a more detailed design with many contact points. Good contact and steady connections help signals move well. Conductive materials help them work in many places.

Note: Pick a low-voltage harness with steady connectors and good contacts. This helps your machines work without problems.

Standards

You must follow rules when using industrial wire harnesses. These rules keep things safe and high quality. The table below shows the main rules and certificates for wire harnesses:

Always ask your wire harness maker for proof of these certificates. This keeps your business safe and follows the law.

Manufacturer Selection

You must pick the right Cable Harnesses maker for your wire harness. Think about these things to make a good choice:

Quality Control: Good checks mean fewer mistakes and better products.

Supply Chain and Logistics: Good planning means you get your harness on time.

Cost Evaluation: Look at all costs, even hidden ones and money changes.

Supplier Relationships: Clear talks and teamwork help your project do well.

Technology and Innovation: Makers who use new tech give you better harnesses.

If you want good advice and strong products, pick a wire harness factory with a good history. Xiamen Kehan Electronics is a trusted company. They follow strict rules and make high-quality harnesses for factories.

3. Aerospace Wire Harnesses

Overview

Aerospace wire harnesses are very important in planes and spaceships. They keep electrical systems safe and neat. The environment in aerospace is tough. There are extreme temperatures, high pressure, and lots of shaking. Wire harnesses must always work in these hard places. They need materials that can handle heat and radiation. These harnesses must also be light to meet weight rules. It is important to use flame-retardant materials and good wire paths. Redundancy means having extra wires for important systems. You should check that harnesses follow FAA rules and AS9100 standards. Working with a skilled wire harness maker helps you get harnesses that meet these needs.

Tip: Pick aerospace wire harnesses that pass strict quality tests. This helps stop problems in important systems.

Key Features

Aerospace wire harnesses have special features that make them different. They protect against interference, electric shock, and fire. Flame-retardant materials help with fire safety rules. EMI/RFI shielding keeps signals clear and stops crosstalk. Redundancy means there are extra wiring paths for key jobs. Good insulation stops short circuits, even high up. Testing checks if harnesses can handle shaking and heat changes. Custom harnesses can fit your aircraft’s needs.

Note: Ask your wire harness maker about their testing steps. Good makers like Xiamen Kehan Electronics give you test reports and certificates.

Applications

Aerospace wire harnesses are used in many parts of planes and spaceships. They send power, data, and signals between devices and systems. They help control engines, wings, and landing gear. Harnesses make it easier to find and fix problems.

You see wire harnesses in avionics, flight control, and navigation. Spacecraft use harnesses for life support, engines, and sending data. Both commercial and military aircraft need these harnesses. Picking a wire harness maker with aerospace skill, like Xiamen Kehan Electronics, helps you meet safety and reliability rules.

Reminder: Always choose a wire harness maker who knows aerospace needs. This keeps your systems safe and working in flight.

Standards

You have to follow strict standards for aerospace wire harnesses. These rules help keep planes safe and working well. Many standards focus on how harnesses handle tough places, save weight, and work with new tech. You also need the right papers and certificates for each harness.

Here are the main aerospace standards for wire harnesses:

Harsh Environment Resistance: The harness must handle hot, cold, shaking, and wet or chemical places.

Weight Reduction and Space Optimization: Using light materials and small designs helps planes use less fuel and work better.

Compatibility with Advanced Technologies: The harness should work with new systems like fly-by-wire and avionics.

Maintenance and Repair Efficiency: Good harnesses make fixing problems faster and easier.

Documentation and Certifications: You need the right papers and certificates to follow safety and quality rules.

Look for wire harnesses that meet these standards:

Tip: Always ask your wire harness maker for proof of certificates. This keeps your plane safe and helps you follow the rules.

Manufacturer Criteria

You need to pick the right wire harness maker for aerospace jobs. The right choice gives you good products and strong help. Look for a wire harness factory with lots of experience and deep knowledge. Xiamen Kehan Electronics is a trusted name in this area.

Here are the top things to think about:

Lots of experience making aerospace wire harnesses.

Knows your industry and what you need.

Can give you cables that fit your tech needs.

Has strong design, making, and testing skills.

Has more than one factory for better delivery.

Can get good parts for your harnesses.

Delivers fast to meet your project times.

Good prices without losing quality.

Follows all rules and has the right certificates.

Gives you personal help and tech support.

Note: Always work with a wire harness factory that knows aerospace rules and gives strong help. Xiamen Kehan Electronics has certified harnesses and expert advice for your aerospace needs.

4. Medical Wire Harnesses

Overview

Medical wire harnesses are very important in healthcare. You see them in machines that help doctors and nurses. These harnesses keep wires neat and safe. This helps medical devices work well and safely. Hospitals need harnesses that can handle water, chemicals, and cleaning. You should pick a wire harness maker who knows about medical equipment. Xiamen Kehan Electronics is a trusted company for healthcare wire harnesses.

Tip: Always make sure your wire harnesses follow medical safety rules before using them with patients.

Key Features

Medical wire harnesses have special features. They help keep patients and staff safe from electrical problems. These harnesses must be strong and easy to clean. The table below shows the main things to look for:

Pick wire harnesses that are safe for people and fight germs. These features help stop infections and keep devices safe. A good wire harness maker like Xiamen Kehan Electronics gives you harnesses that follow medical rules.

Note: Medical wire harnesses must pass tough tests for safety and strength. Always ask your wire harness maker for proof of these tests.

Applications

Medical wire harnesses are used in many healthcare machines. They connect sensors, power, and controls. This helps devices work well and send data fast. Here are some common uses:

MRI, CT, and ultrasound machines: Connect sensors, power, and controls, help make clear pictures.

Patient monitors: Watch heart rate and other signs, send data right away.

Surgical tools and robots: Move power and data for surgery.

Portable diagnostic devices: Connect sensors in small tools for emergencies.

Infusion pumps and drug delivery: Give medicine safely and check device status.

Diagnostic Equipment: MRI, CT, and X-ray machines.

Surgical Tools: Robotic systems and devices for surgery.

Patient Monitoring Systems: ECG and EEG for quick data.

Therapeutic Equipment: Ventilators and dialysis machines.

Wearable Devices: Small tools for diagnosis and treatment.

Work with a wire harness maker who knows medical needs. Xiamen Kehan Electronics makes custom harnesses for hospitals and labs.

Tip: Pick a wire harness maker who can make harnesses for your special medical machines. This helps keep every patient safe and your devices working well.

Standards

You have to follow strict rules for medical wire harnesses. These rules keep patients safe and help devices work well. Always check if your wire harness maker follows all the rules.

Medical wire harnesses must meet safety rules like ISO, UL, and FDA.

Harnesses need to be safe for people and not toxic.

The harness should handle cleaning and sterilizing.

It must be strong and bend easily to work well in hospitals.

ISO 13485 is the main rule for making safe medical devices. If your wire harness factory follows ISO 13485, they care about safety and quality. FDA rules also control medical devices and their parts. These rules make sure every wire harness is safe and works right.

Tip: Always ask your wire harness maker for proof of ISO 13485 and FDA approval. This helps you stay safe and keeps your devices working for patients.

Manufacturer Considerations

You need to pick a wire harness maker who knows medical device needs. The right company helps you get safe and custom harnesses for your machines. Xiamen Kehan Electronics is a trusted wire harness factory with lots of skill in medical jobs.

Pick a wire harness maker with strong quality checks. This helps stop mistakes and keeps devices safe.

Choose a factory that can make harnesses just for you. You get harnesses that fit your machines.

Check if the factory can make and deliver many harnesses fast.

Good customer support helps your project go smoothly. You get help quickly and avoid waiting.

Note: Xiamen Kehan Electronics gives expert help, custom harnesses, and certified products for medical jobs. You can trust their team to help you follow every rule and keep your devices safe.

5. Custom & Specialty Wire Harnesses

Overview

Sometimes, regular wire harnesses do not work for your project. Custom and specialty wire harnesses let you pick what you need. You can choose the length, connector, and wire type. These harnesses help with special problems in many industries. They are used in aerospace, medical, telecommunications, and factories. You get a harness that fits your equipment and where you use it. This makes it easier to install and fix later. It also helps you follow safety and quality rules. A skilled wire harness maker will make sure your harness is just right.

Tip: Custom wire harnesses can help you save time and money. They lower downtime and make repairs easier.

Key Features

Custom and specialty wire harnesses have many good features. You can pick the best materials for your job. Shielding keeps signals safe from outside noise. Each harness has connectors that fit your devices. The harness is bundled, covered, and labeled so you know what each part does. Testing makes sure the harness is safe and works well. Wires are routed neatly to make setup easy. Labels help you avoid mistakes when installing. Strong materials help the harness last in tough places.

Note: Always ask your wire harness maker how they test and label harnesses. This helps you avoid mistakes and keeps your system working well.

Applications

Custom and specialty wire harnesses are used in many fields. You see them in planes, hospitals, phone networks, and factories. Each job needs a different kind of harness. Coaxial harnesses send high-frequency signals with little noise. Round cable harnesses are good when you need wires to bend and last. Multi-conductor harnesses connect many devices at once. Hybrid harnesses carry power, data, and control signals together. High-temperature harnesses work in hot places like engines. Waterproof harnesses keep wires safe from water in boats or outside. Custom harnesses are made for special jobs with unique needs.

Aerospace: You need harnesses for plane controls and systems.

Medical: You use harnesses in machines that check or watch patients.

Telecommunications: You need harnesses for sending signals and setting up networks.

Manufacturing: You use harnesses in robots and factory machines.

Tip: If you need a harness for a special job, work with a Cable Harnesses maker who can build custom solutions. Xiamen Kehan Electronics can help with expert advice and special designs for your needs.

Customization Options

You have many ways to customize a specialty wire harness. These choices help you fix special problems and fit your project. You can pick the length, connector, and wire material you need. Some features make it easier to put in and help it work better.

Here is a table that lists common customization choices and what they do:

You can ask for shielding to stop interference or waterproofing for outside use. Some harnesses work in hot places or can handle chemicals. You might want wires with colors to tell them apart. Labels and neat wire paths help you not make mistakes when you put it in.

Tip: Always tell your wire harness maker what you need. Custom choices make your system safer and easier to fix.

Manufacturer Selection

Picking the right maker for custom wire harnesses is very important. You want someone who knows your industry and makes good products. Look for a factory that has worked on projects like yours, such as cars, hospitals, or factories.

Here is a table to help you compare different makers:

Ask these questions when you talk to a Cable Harnesses maker: Do you have experience in my field? Can you show examples of your work? What do you do to check quality?

You should think about working with Xiamen Kehan Electronics. They know a lot and make custom harnesses for many jobs. Their team helps you and follows strict rules for quality. You get good harnesses and smart advice for your project.

Note: The right wire harness maker helps you avoid waiting and makes sure your harness is safe and works well.

Choosing the Right Wire Harness

Assessing Needs

First, you need to know what your project needs. Every job is different and has its own needs. Think about these main things:

Environmental Conditions: Find out if the harness will face heat, water, chemicals, or dust. These things change what materials you should use and how long the harness will last.

Flexibility Requirements: Decide if the harness must bend or move a lot. Flexible harnesses work better in moving parts or small spaces.

Electrical Requirements: Make sure the harness can handle the voltage and current your system uses. This stops it from getting too hot or breaking.

Material Selection: Choose materials that fit your job and where you use the harness. PVC, XLPE, and TPU are often used for insulation and covers.

Connector Compatibility: Check that the harness fits your connectors and equipment.

EMI Protection: If your system has electromagnetic interference, pick harnesses with shielding.

Installation Ease: Choose harnesses that are easy to put in and take care of. This saves time and helps you make fewer mistakes.

Quality Control: Ask your wire harness manufacturer about their quality checks. Good quality checks mean better and safer harnesses.

Tip: Write down what you need before you talk to a wire harness factory. This helps you get the right harness faster.

Environment & Safety

Safety and the environment are very important when picking a wire harness. You need to keep your system and people safe from harm. Think about these things:

Temperature Resistance: Pick harnesses that can handle hot and cold. This keeps them working in any weather.

Vibration Durability: Choose harnesses that are tested for shaking. Machines and cars shake a lot, so strong harnesses last longer.

Water and Chemical Protection: Use harnesses with covers that block water and chemicals. This helps them last in tough places.

Electrical Load Testing: Make sure the harness passes tests for voltage and current. This stops it from getting too hot or failing.

Shielding for EMI: Use harnesses with shielding if your system has electromagnetic interference.

Safety Standards: Pick harnesses that meet safety rules for your job.

Note: Always ask your wire harness factory for test reports. This shows the harness is safe and works in your environment.

Compliance

You must follow the rules for your industry to keep your system safe and legal. Every industry has its own rules. Here is a table with common standards and what they mean:

Certifications like IPC/WHMA-A-620 help you get good quality and fewer problems. These rules are important for safety and making sure things work right. Always ask your Cable Harnesses manufacturer for proof they follow the rules. This keeps your project safe and helps you avoid trouble.

Tip: Work with a wire harness manufacturer who knows your industry’s rules. Xiamen Kehan Electronics gives certified harnesses and smart advice for every job.

Customization

You can change wire harnesses to fit your project. Customization helps you fix problems and make things work better. You pick the wire length, connector type, and insulation material. You also choose features like shielding, waterproofing, and color coding.

Here are some common ways to customize:

Wire Length and Gauge

You pick the right length and thickness for your system. This stops extra wire and keeps things tidy.Connector Type

You choose connectors that fit your devices. This makes setup simple and helps you avoid mistakes.Insulation and Sheathing

You select materials that protect wires from heat, water, and chemicals. This keeps your harness safe in hard places.Shielding

You add shielding to block electromagnetic interference. This keeps your signals strong and clear.Labeling and Color Coding

You use labels and colors to tell wires apart. This makes installing and fixing faster.Bundling and Routing

You group wires together for easy setup. This saves time and lowers work costs.

Tip: Always talk with your wire harness manufacturer about what you need. Custom choices help you get a harness that fits and lasts longer.

Cable Harnesses Manufacturer Selection

Picking the right Cable Harnesses manufacturer is important for your project. You want a partner who knows your industry and gives good products. Here are steps to help you choose well:

Check Experience

Find a wire harness factory with experience in your field. They know what works and what does not.Review Certifications

Ask for proof of industry standards. Certifications show the manufacturer cares about safety and quality.Evaluate Customization Capabilities

Make sure the manufacturer can make custom harnesses for your needs. This helps you get the right fit.Assess Quality Control

Ask about their testing and inspection process. Good quality control means fewer problems.Consider Customer Support

Pick a manufacturer who answers questions and helps you quickly.Compare Delivery Times

Fast delivery keeps your project moving. Ask about their production and shipping speed.

Note: Xiamen Kehan Electronics is a trusted wire harness factory. They offer certified products, custom solutions, and strong support. You can count on their team for expert advice and quality harnesses.

You make things safer and better when you work with a skilled Cable Harnesses manufacturer. Always ask questions and check references before you choose.

You learned about five main wire harness types. These are automotive, industrial, aerospace, medical, and custom or specialty. Each type does a special job and works in certain places. Picking the right harness helps keep things safe and working well. You should talk to a trusted Cable Harnesses manufacturer for help. Xiamen Kehan Electronics can help you find the best harness. You can ask their team for details or a price.

Think about what you need.

Talk to people who know a lot.

Ask for a harness made just for you.

Tip: The right harness helps your system stay safe and work better.

FAQ

What is a wire harness?

A wire harness keeps wires together and safe. It helps organize cables in your equipment. This stops wires from getting hurt. It also makes sure power or data moves safely.

How do you choose the right wire harness manufacturer?

Pick a wire harness maker with lots of experience. They should have good quality checks and important certificates. Xiamen Kehan Electronics gives strong support and good products for many jobs.

Why do different industries need special wire harnesses?

Every industry has its own needs and problems. Planes need harnesses that are light and can take heat. Medical machines need harnesses that are safe and easy to clean. You must pick a harness that fits your job and place.

What certifications should a wire harness factory have?

Look for certificates like ISO 9001, IPC/WHMA-A-620, or ISO 13485. These show the factory follows safety and quality rules.

Can you customize a wire harness for your project?

Yes, you can get a wire harness made just for you. You pick the wire length, connectors, insulation, and labels. Xiamen Kehan Electronics can make special harnesses for hard jobs.

How do you maintain a wire harness?

Check your harness often for damage or loose parts. Change broken pieces right away. A good wire harness maker can give you tips and help with care.

What makes Xiamen Kehan Electronics a trusted brand?

Xiamen Kehan Electronics uses new machines and strong checks. They have important certificates. You get smart advice and wire harnesses you can trust for any job.