Classification, advantages and process requirements of wire harness terminal connection methods

2025-12-26 15:24A Deep Dive into Wire Harness Terminal Core Technologies: Classification, Advantages, and Precision Process Requirements

In the precise engineering field of wire harness manufacturing, terminal connections are the critical link determining the reliability, safety, and long-term stability of an entire electrical system. Whether it's an automotive wiring harness for the engine bay, an industrial equipment harness for factory automation, a medical device wire harness, or a new energy vehicle high-voltage harness, different connection methods are suited to specific application scenarios and stringent requirements. As a professional wire harness and connector manufacturer with years of industry experience, KeHan Electronics deeply understands the essence of each connection technology and translates it into the cornerstone for ensuring the excellent performance of our clients' products. This article will systematically analyze various wire harness connection methods and delve into how advanced processes, represented by crimping, provide flawless connection solutions for your custom wire harness projects through scientific management and precise control.

I. A Comprehensive Taxonomy of Wire Harness Connection Methods and Deep Application Analysis

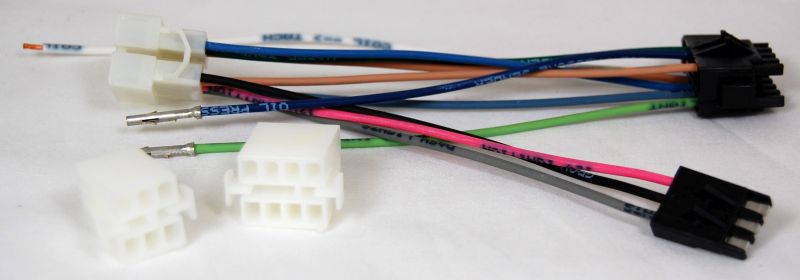

A wire harness is not merely a collection of wires; it's a systems engineering project composed of various precision connection technologies. Here is a professional interpretation of five mainstream connection methods:

1. Soldering – The Paradigm of Precision Micro-Connections

The most common type is tin soldering. Its core lies in forming a stable intermetallic compound between the solder and the metal surfaces being joined, achieving electrical continuity. It is suitable for signal transmission, microelectronics, and internal connections in some consumer electronic wire harnesses with strict volume limitations. However, its strength is greatly influenced by process skill, and the high temperature may cause thermal stress to adjacent components.

2. Crimping – The Industrial Standard for High Reliability and Efficiency

Crimping is a process that uses precisely controlled mechanical force to cause plastic deformation and displacement of the wire terminal (crimp barrel) and wire metal within defined limits, forming a permanent connection akin to "cold welding." It produces excellent mechanical strength and stable low-resistance electrical continuity, particularly adapting to harsh environments like vibration, high-low temperature cycles, and high current. In modern automotive engine harnesses, construction machinery harnesses, and any wire harness assembly requiring high reliability, crimping has become the irreplaceable preferred process. KeHan Electronics is equipped with a complete system ranging from fully automatic crimping machines to precision manual tools, ensuring perfect crimping solutions for wires with cross-sections from 0.1 mm² to 100 mm² and above.

3. Wire Wrapping – The High-End Choice for Hermetic Connections

This involves tightly wrapping the wire around a square-post terminal, relying on strong contact pressure to form a gas-tight point. This connection offers extremely high reliability and vibration resistance, commonly found in specialized wire harnesses for aerospace, high-end military equipment, and communication backplanes where ultimate reliability is demanded.

4. Insulation Displacement Connection (IDC) – The Representative of Efficient Automation

This method requires no pre-stripping. It utilizes unique "U"-shaped spring contacts within the connector to pierce the wire insulation, making direct contact with and clamping the conductor. This technology significantly improves wire harness processing efficiency and ensures connection consistency. It is widely used in connectorized wire harnesses, such as IDC ribbon cables, FFC flat flexible cables, and for the rapid assembly of many automotive interior wire harness components.

5. Screw Terminal Connection – The Flexible and Reliable Power Interface

This method uses screw-type terminal blocks, achieving connection through thread pressure. This approach offers installation flexibility, ease of maintenance and inspection, and is suitable for power distribution harnesses, ground terminals and power input points in industrial control cabinet harnesses, and power distribution occasions requiring frequent modifications.

II. Why Crimping is the Golden Rule for High-End Wire Harness Manufacturing?

In KeHan Electronics' manufacturing philosophy, crimping is not just a process; it is a commitment to ensuring the long-term reliable operation of the complete wire harness assembly. We advocate for crimping due to its unparalleled comprehensive advantages:

Excellent Electromechanical Performance: The formed "cold weld" joint exhibits conductivity close to the base metal and excellent tensile strength, far superior to soldering, with no heat-affected zone.

Outstanding Environmental Tolerance: The joint resists corrosion and vibration, fully meeting the stringent requirements of automotive wiring harnesses within engine compartments and industrial harnesses under continuous vibration.

High Degree of Process Consistency and Traceability: By controlling key parameters like crimp height and crimp force, each connection point is measurable, repeatable, and traceable, providing a guarantee for quality stability in mass wire harness production.

Environmental and Production Friendliness: The entire process is lead-free and generates no toxic gases, complying with green manufacturing standards and protecting operator health.

Excellent Scalability for Mass Production: Perfectly complements KeHan Electronics' automated wire harness production lines, enabling high-efficiency, low-cost customized mass production.

III. KeHan Electronics' Precision Control System for Crimping Processes: From Theory to Perfect Practice

We deeply understand that superior theoretical advantages must be translated into reliable product performance through meticulous process control. KeHan Electronics has established a complete crimping process control system:

1. Precise Pre-processing and Material Control

Scientific Wire Stripping: Utilizing servo-controlled wire strippers to ensure strip length tolerances are precise to ±0.2mm (e.g., formula: barrel length + 1mm), with clean, smooth cuts that absolutely guarantee the integrity of the copper strand twisted structure, with no broken strands.

The Golden Match of Wire and Terminal: Based on your electrical schematic and 3D wire harness layout, we select and match high-quality terminals and connectors that perfectly complement the wire cross-section and insulation diameter, ensuring compatibility from the source.

2. Parametric and Visual Control of the Core Crimping Process

Alignment and Insertion: Guided fixtures ensure the wire is fully inserted to the bottom of the crimp barrel, and the distance between the insulation jacket and the barrel mouth is strictly controlled within the standard range (e.g., <1mm).

Closed-Loop Optimization of Crimp Parameters: We regard crimp depth and indentation position as lifelines. Through an extensive process validation database, we have locked in the optimal crimping program for each terminal-wire combination. For instance, for the aforementioned 1.0mm² wire, our system automatically sets the crimp depth within the peak tensile force range (e.g., 1.5mm-1.7mm), perfectly balancing connection strength and conductor integrity.

Real-Time Monitoring and Feedback: Key stations are integrated with visual inspection systems, performing 100% checks on post-crimp terminal appearance, bell mouth shape, and wire position. Any deviation triggers a system alarm and stoppage.

3. Comprehensive Quality Verification and Continuous Improvement

Institutionalized Destructive Testing: Pull force tests and voltage drop tests are conducted daily and per batch. Data is recorded in real-time into an SPC (Statistical Process Control) system, generating X-R control charts to achieve predictive quality trend management.

The Gold Standard of Cross-Section Analysis: Metallographic cross-section analysis is performed on the first article of all new projects and new molds/tooling. Examining under a high-power microscope verifies whether internal metal flow is sufficient and uniform and free of voids. This is our "final exam" before approving mass production.

Tool Lifecycle Management: Crimp dies undergo strict crimp cycle counting and regular maintenance. A force curve analyzer monitors the force-displacement curve of each crimp, ensuring tools are always in optimal condition.

IV. Connecting the Future, Choosing a Professional Partner

In today's rapidly developing landscape of connection technologies, the value of a wire harness far exceeds its material cost; it carries the functional safety and operational mission of the entire system. Relying on its deep integration of connector technology, wire harness processing technology, and industry application standards, KeHan Electronics translates rigorous engineering theory into precise daily practice.

Whether your challenge is designing a new energy vehicle high-voltage harness resistant to 200°C temperatures, requiring large-volume, zero-defect delivery of autonomous driving sensor harnesses, or managing small-batch, high-mix custom industrial robot harnesses, KeHan Electronics is your trustworthy partner. We provide not just a wire harness, but a complete solution encompassing wire harness design, prototype development, mass manufacturing, and test validation.

Let reliable connections become the most solid cornerstone of your product. Welcome to contact Xiamen Kehan Electronics Co., Ltd. Let us use our professional technology and dedicated attitude to safeguard the success of your next project.