Modular Customized Wire Harnesses: How Plug-and-Play Design Cuts Maintenance Costs by 70% in Energy Storage and Industrial Equipment

2026-01-14 10:27As global energy storage systems and industrial equipment grow in scale and complexity, maintenance efficiency has become a decisive cost factor. In 2025, modular customization and plug-and-play architectures are rapidly replacing traditional hard-wired assemblies. At the center of this shift is the High Reliability Wire Harness, which is no longer viewed as a passive component, but as a critical system enabler. For battery energy storage systems, the rise of the modular wire harness for BESS is proving especially transformative, delivering measurable reductions in downtime, labor hours, and lifecycle costs.

Industry Pressure: Why Maintenance Costs Have Become Unsustainable

Energy storage plants and industrial automation lines often operate in harsh environments with strict uptime requirements. Conventional point-to-point wiring creates dense cable routing, high installation complexity, and elevated risk during servicing. In contrast, modular architectures based on custom industrial wiring solutions allow technicians to isolate, replace, and upgrade subsystems without disturbing adjacent circuits.

This transition is accelerating demand for Special Application Cable Solutions that support vibration resistance, high mating cycles, and stable electrical performance under thermal stress. Manufacturers capable of delivering such systems at scale are increasingly recognized as a China High-end Wire Harness Manufacturer within the global supply chain.

Plug-and-Play Design: From Concept to Cost Reduction

The core advantage of modular harnesses lies in standardized interfaces. By replacing fixed wiring with pre-engineered modules, maintenance teams can reduce on-site troubleshooting time by up to 70%. Each High Reliability Wire Harness is assembled, tested, and validated before installation, eliminating field errors.

In energy storage environments, a modular wire harness for BESS enables battery racks, PCS units, and monitoring modules to be serviced independently. This approach significantly lowers operational risk while extending system lifespan. When combined with custom industrial wiring solutions, operators gain flexibility without sacrificing compliance or performance.

Manufacturing Capability as a Differentiator

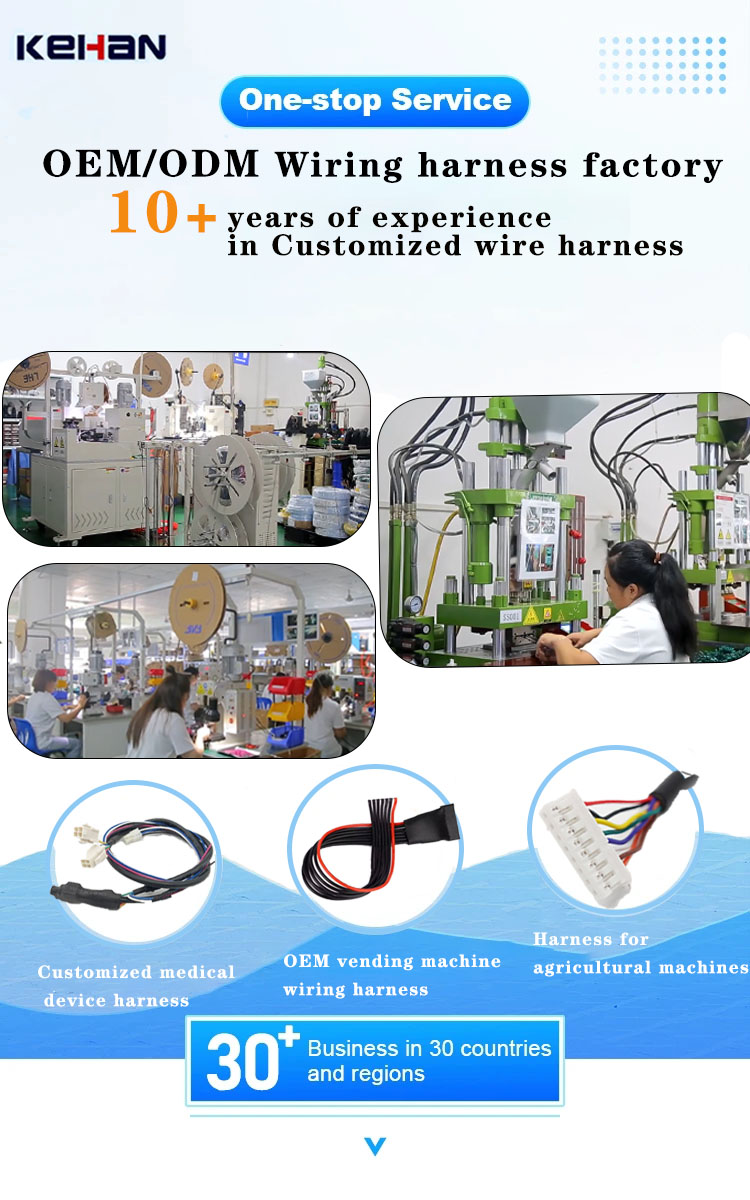

Not all suppliers can support this level of modular engineering. Xiamen Kehan Electronics Co., Ltd., founded in 2010, has built its reputation as a China High-end Wire Harness Manufacturer by integrating R&D, precision manufacturing, and rigorous quality control. With over 200 employees—including technicists and experienced QC staff—the company supports high-mix, low-volume and scalable production alike.

Its portfolio of Special Application Cable Solutions spans industrial automation, energy storage, medical equipment, and electronic appliances. Long-term partnerships with JST and MOLEX further strengthen supply stability, enabling Kehan to deliver consistent High Reliability Wire Harness systems for demanding applications.

Technical Comparison: Traditional vs. Modular Harness Architecture

| Parameter | Traditional Wiring | Modular Harness System |

| Installation Time | Long | Short |

| Maintenance Labor | High | Reduced up to 70% |

| Error Risk | High | Low |

| Scalability | Limited | High |

| Replacement Method | On-site rewiring | Plug-and-play module swap |

| Typical Application | Fixed equipment | BESS & industrial platforms |

This evolution reinforces the importance of custom industrial wiring solutions that align electrical, mechanical, and operational requirements from the design stage.

Energy Storage Systems: A Natural Fit for Modularization

Battery energy storage systems are inherently modular. Aligning electrical architecture with physical modularity unlocks significant efficiencies. A modular wire harness for BESS supports rapid expansion, predictive maintenance, and standardized spare parts management.

To function reliably, these systems depend on Special Application Cable Solutions engineered for long service life and repeated connection cycles. As a China High-end Wire Harness Manufacturer, Kehan addresses these demands through controlled processes, ISO 9001:2015 certification, and compliance with ROHS, REACH, and UL standards.

Frequently Asked Questions (FAQ)

Q1: Why do modular harnesses reduce maintenance costs so dramatically?

Because faults can be isolated and resolved by replacing a single High Reliability Wire Harness module instead of troubleshooting complex wiring networks.

Q2: Are modular systems suitable for harsh industrial environments?

Yes. When designed as Special Application Cable Solutions, modular harnesses can meet vibration, temperature, and ingress protection requirements.

Q3: Is customization still possible with modular designs?

Absolutely. Modularization enhances, rather than limits, custom industrial wiring solutions by standardizing interfaces while allowing internal variation.

Q4: What makes BESS applications different from other industrial systems?

High current density and scalability demands make the modular wire harness for BESS particularly valuable for long-term operation.

Call to Action: Rethinking Wiring as a Strategic Asset

As energy storage and industrial automation continue to scale, wiring architecture must evolve accordingly. Partnering with a capable China High-end Wire Harness Manufacturer allows system integrators to reduce maintenance costs, improve uptime, and future-proof their installations.

Xiamen Kehan Electronics invites global customers to explore modular, plug-and-play High Reliability Wire Harness systems engineered for real-world operating conditions.

Conclusion: Modular Harnesses Define the Next Cost Curve

The shift toward modular customization marks a structural change in how industrial and energy storage systems are built and maintained. By combining standardized interfaces with custom industrial wiring solutions, operators gain both efficiency and resilience.

Through its focus on Special Application Cable Solutions and advanced manufacturing capability, Xiamen Kehan Electronics continues to support the global transition toward smarter, more maintainable electrical systems—where the modular wire harness for BESS is no longer optional, but essential.