Beyond Connectivity: A New Paradigm for Reliability and Intelligent Management of ESS Wiring Harnesses

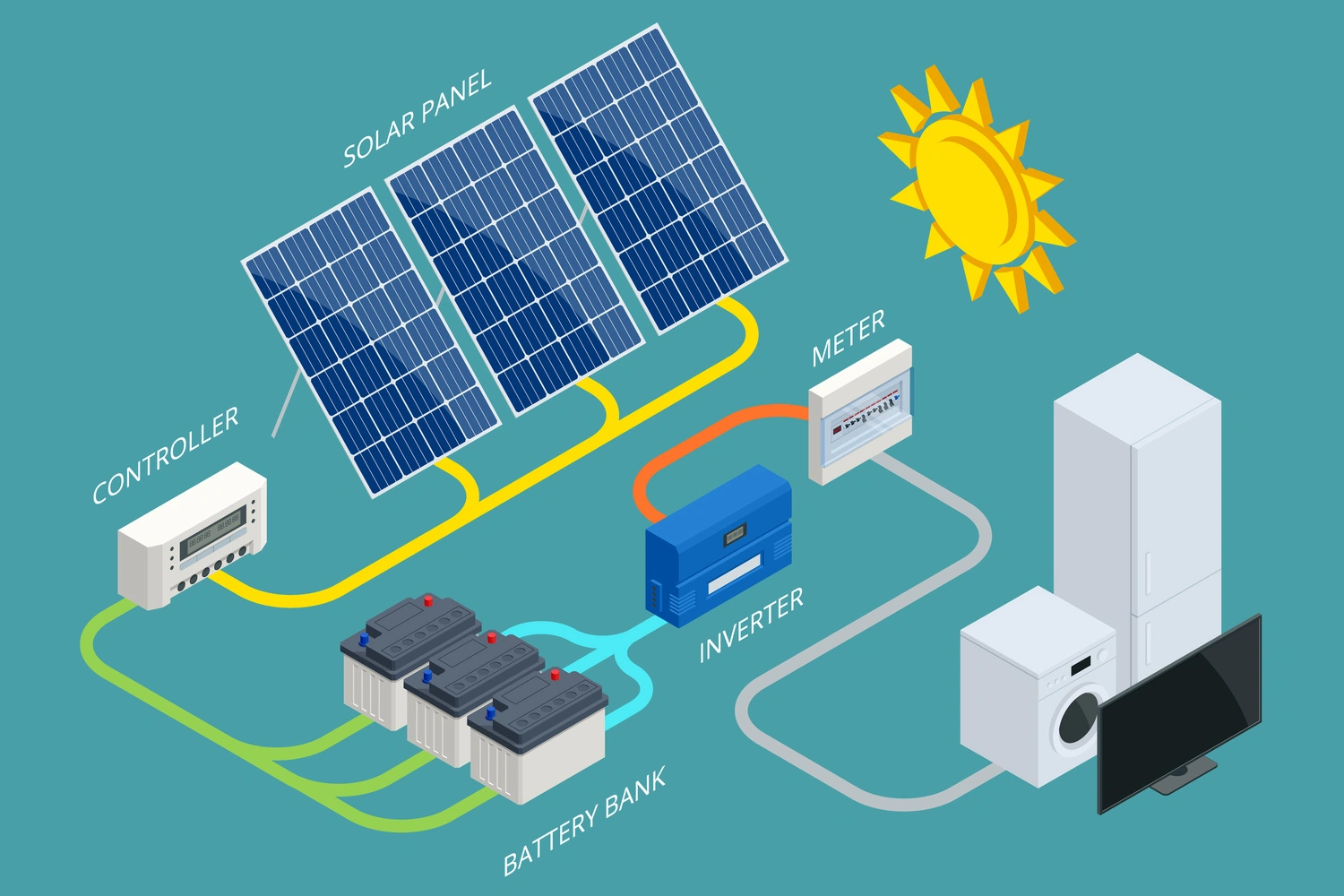

2025-11-28 10:40As the global renewable energy revolution accelerates, Energy Storage Systems (ESS)have become a critical infrastructure for flexible power grid management and renewable energy integration. However, recent fire incidents at ESS power stations have once again sounded the alarm for safety management. Investigations show that overloaded or loose wiring harnesses within battery clusters often act as the trigger for thermal runaway and cascading failures.

In response, Xiamen Kehan Electronics Co., Ltd. has proposed the concept of “beyond physical connectivity,” positioning wiring harnesses as the core backbone of ESS safety and efficiency. By integrating intelligent sensors, modular design, and standardized materials, Kehan provides a value-added solution that transforms ESS operations from “passive response” to proactive prevention, helping clients achieve safer, more stable, and higher-efficiency energy storage.

I. Pain Points of ESS Wiring Harnesses

Although wiring harnesses are merely conduits connecting battery modules, their role in ESS performance is far from trivial. Traditional wiring harnesses face four major pain points:

1. Thermal Runaway Risk

Overloaded or poorly connected wires create local hotspots within battery clusters. Without timely monitoring, these hotspots can trigger chain-reaction thermal runaway, causing system damage or fire.

2. Maintenance Challenges

Traditional wiring harnesses lack real-time status data, making fault localization labor-intensive, costly, and slow.

3. Energy Efficiency Loss

Uneven contact resistance, insulation aging, or poor connectivity leads to energy losses, reducing the overall efficiency of the ESS.

4. Complex Wiring and High Costs

Modern ESS installations involve numerous harnesses; on-site installation is complicated, error-prone, and labor-intensive.

These challenges underscore a fundamental problem: traditional harnesses function only as passive conductors, incapable of providing proactive safety management or intelligent operations.

II. Intelligent Wiring Solutions: From Connectivity to Management

To address these challenges, Kehan Electronics offers integrated smart wiring harness solutions centered on real-time monitoring, predictive maintenance, and modular management. Key features include:

1. Integrated Sensor Harnesses

Temperature and current sensors are embedded at critical points, enabling real-time monitoring of harness health. Integrated with the Battery Management System (BMS), early warnings can be triggered before minor anomalies escalate.

2. Predictive Maintenance

Through data analytics platforms, trends in loose connections, insulation aging, or overload are detected in advance, enabling proactive interventions and preventing unplanned downtime.

3. Modular Design

Plug-and-play battery-to-battery harnesses significantly reduce on-site installation time and error rates, improving construction efficiency and system consistency.

4. Material Selection and Standards

Flame-retardant, oil-resistant, and high-temperature materials ensure long-term reliability under harsh conditions. All products comply with UL certification, ROHS, and REACH standards, providing both safety and environmental assurance.

With this intelligent design, Kehan Electronics addresses traditional wiring harness challenges while providing a robust foundation for high-efficiency ESS operations.

III. Industry Analysis Parameters

| Parameter | Traditional Harness | Kehan Smart Harness | Improvement |

|---|---|---|---|

| Overload Alarm Response Time | 5–10 min | ≤1 min | >80% faster |

| Fault Localization Time | 2–4 hours | 10–30 min | >85% faster |

| Installation Time (per battery cluster) | 30 min | 10 min | 66% faster |

| Thermal Runaway Risk | High | Low | Significantly reduced |

| Energy Loss | 1.5–2% | ≤0.5% | ~3× lower |

| Customization Flexibility | Low | High | Highly flexible |

| Maintenance Labor Cost | High | Medium-low | ~50% reduction |

The data clearly shows that smart ESS wiring harnesses greatly enhance system safety, reduce maintenance costs, and optimize energy efficiency.

IV. Typical Application Case

Background: A commercial-scale ESS project, 200 MWh installed capacity, faced low maintenance efficiency with conventional wiring harnesses. Response times exceeded two hours, and energy efficiency fluctuated.

Solution:

Kehan Electronics delivered a full set of Energy Storage System (ESS) Wiring Harness and Smart Battery Cable Assembly, integrated with a BMS Integrated Wiring Loom for real-time data collection and fault warning. Photovoltaic Energy Storage Cables were provided for rapid modular deployment.

Results:

Maintenance response time reduced by 70%; on-site labor demand decreased by 50%.

System energy efficiency improved by ~12%, reducing power loss.

Battery cluster failure rate dropped by 60%, significantly enhancing system reliability.

This case demonstrates how a Custom ESS Harness Manufacturer like Kehan can elevate ESS management from passive monitoring to proactive prevention.

V. Core Product Keywords in Context

Energy Storage System (ESS) Wiring Harness — the backbone of ESS safety and energy efficiency, offered as a full custom solution.

Smart Battery Cable Assembly — integrates temperature and current sensors for real-time monitoring and data acquisition.

BMS Integrated Wiring Loom — seamlessly connects with the battery management system for predictive maintenance and early warnings.

Photovoltaic Energy Storage Cables — reliable, modular, and easy-to-deploy harnesses for PV-linked ESS projects.

Custom ESS Harness Manufacturer — provides high flexibility for projects of varying scale and application scenarios.

VI. FAQ

Q1: Can Kehan’s smart harness adapt to different ESS capacities?

A: Yes, modular design covers systems from small residential ESS to large commercial installations.

Q2: Are installation processes complex?

A: No. Plug-and-play design reduces installation time per cluster to one-third of conventional harnesses and minimizes errors.

Q3: Does data collection require extra hardware?

A: No. Kehan harnesses connect directly to the BMS for real-time monitoring without additional units.

Q4: Do the materials meet international safety standards?

A: Yes. All products meet UL, ROHS, and REACH standards and use flame-retardant, oil-resistant, and high-temperature materials.

Q5: What is the lifespan of the harnesses?

A: Under normal conditions, Kehan smart harnesses can last over 10 years and support predictive maintenance.

VII. Call to Action

The safety and efficiency of energy storage projects depend not only on the battery but also on every harness connecting it. Choosing intelligent, modular, and predictive maintenance-ready harness solutions is the key to long-term stability.

Book a Smart Wiring Solution Demo Today — Kehan Electronics will provide:

Customized Energy Storage System (ESS) Wiring Harness designs;

BMS integration and real-time monitoring demonstrations;

Modular installation and maintenance efficiency optimization consultation.

Upgrade your ESS from reactive response to proactive prevention, improving safety, reducing costs, and enhancing energy efficiency — empowering the global clean energy transition.