Empowering Electric Mobility: How Next-Generation High-Voltage Wire Harnesses Safeguard the Safety and Performance Limits of Electric Vehicles

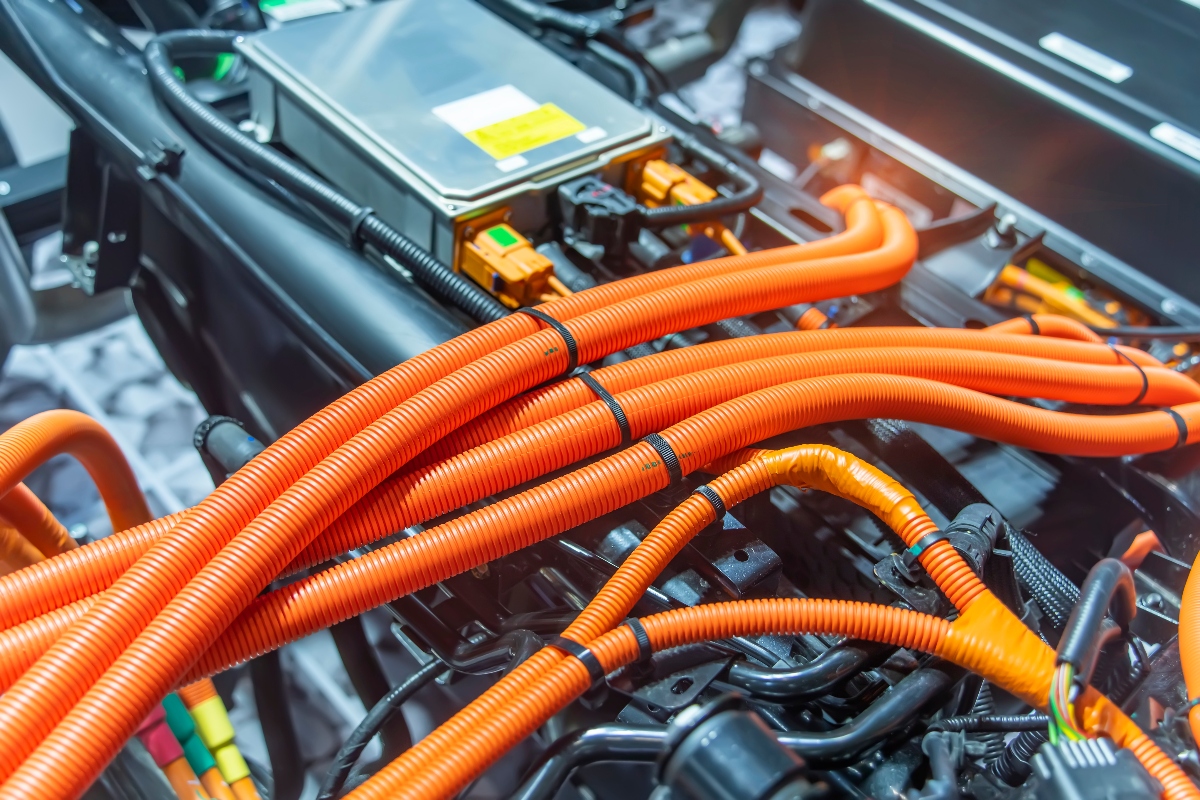

2025-11-24 10:16As the global electric vehicle (EV) industry enters the era of high-voltage and ultra-fast charging, every cable inside the car is no longer a simple “connector,” but rather a neural network transmitting energy and data. Especially with 900V and even 1000V high-voltage platforms becoming the new mainstream, the safety, durability, and EMC (Electromagnetic Compatibility) performance of high-voltage wire harnesses have become the core factors that define a vehicle’s performance ceiling and safety baseline.

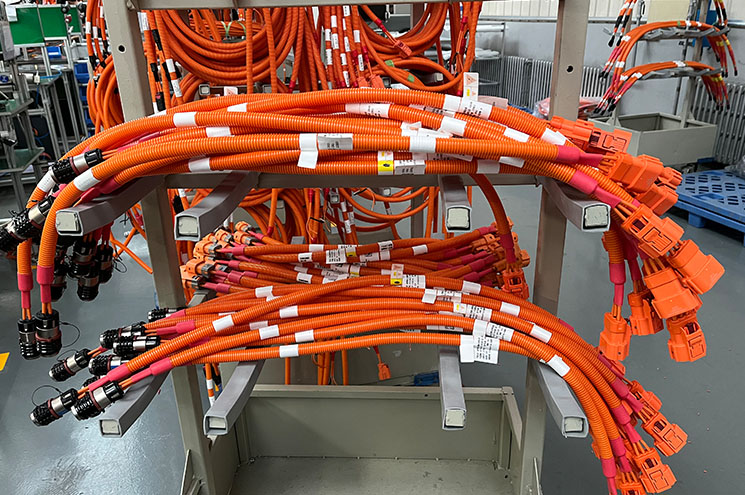

This article spotlights Xiamen Kehan Electronics Co., Ltd., a leading wire harness manufacturer in China, showcasing how it leverages material innovation, connection engineering, and EMC design to help global EV makers push the limits of safety and performance in the age of high-voltage mobility.

1. Industry Trend: The “Wire Harness Revolution” in the High-Voltage Era

The competition in the EV industry is shifting from battery energy density to system power efficiency. To achieve:

Faster charging speeds (e.g., 10-minute recharge for 400 km range)

Higher power conversion efficiency (900V/1000V systems)

Lighter vehicle weight

Manufacturers are upgrading to high-voltage architectures. However, higher voltage brings greater risks — electrical arcing, insulation breakdown, and EMI challenges.

Under this trend, the wire harness has been redefined — no longer just a “wire,” but the lifeline of vehicle energy and safety. This is precisely where Kehan Electronics has been focusing its R&D efforts for over 15 years.

2. Key Challenges: From “Connection” to “Protection”

1. High-Voltage Risk – The Invisible Threat of Arcing

On 900V and above systems, even a minor insulation flaw can trigger arc discharge. High-voltage arcing not only causes power loss but can burn conductors, damage connectors, and even lead to fires.

Kehan’s engineering team emphasizes:

“High-voltage safety isn’t just about materials — it’s a system-level challenge that involves insulation design, creepage distance, and moisture protection.”

2. Thermal Management Challenge – The “Heat Stress” of Fast Charging

With 800V fast-charging becoming mainstream, wire harnesses must endure sustained high currents and extreme heating. Traditional PVC or rubber insulation tends to degrade under such thermal stress.

Kehan counters this with high-grade silicone insulation and ceramic flame-retardant materials, maintaining insulation integrity at up to 200°C, ensuring long-term reliability and fire safety.

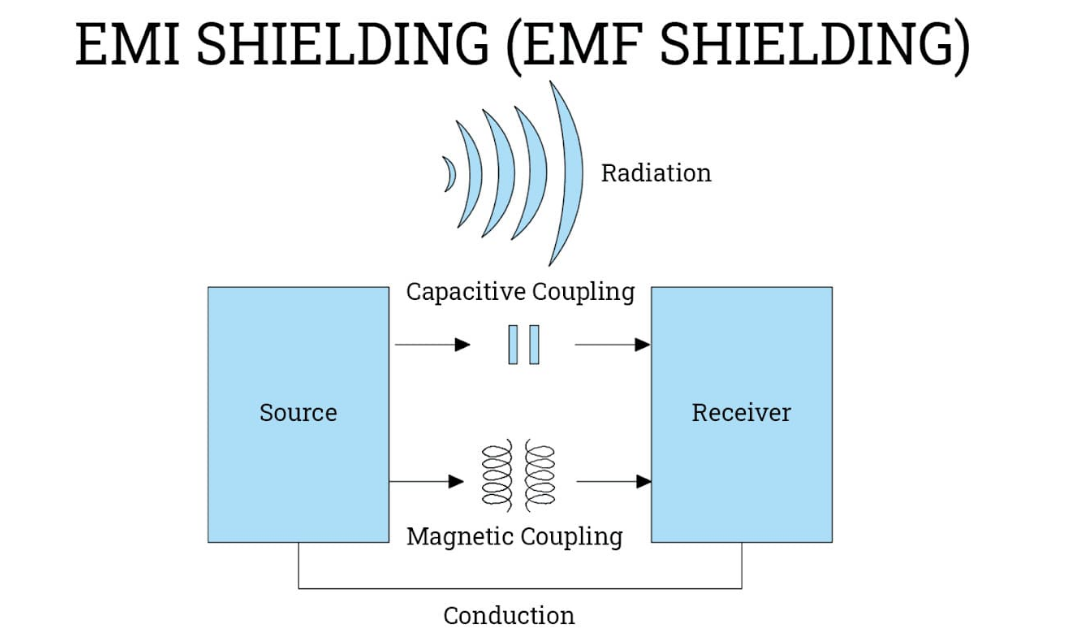

3. Signal Integrity – EMI in High-Voltage Systems

Inside EVs, high-voltage cables often run alongside low-voltage communication lines such as CAN bus and BMS connections. Switching surges can generate severe EMI that disrupts signal stability.

Kehan’s design approach uses optimized shielding density and grounding architecture to minimize EMI coupling at the source — validated through lab-level EMC testing to ensure zero signal interference.

4. Durability & Environmental Resistance

From -40°C alpine conditions to 60°C desert heat, from salt spray corrosion to mechanical vibration, EV harnesses must perform consistently throughout the vehicle’s lifecycle.

Every Kehan harness undergoes:

IP67 waterproof and dustproof testing

72-hour vibration fatigue testing

Thermal shock cycles (-40°C ~ 125°C)

These ensure stable performance under the most demanding real-world conditions.

3. Kehan’s High-Voltage Solution: Engineering Safety by Design

| Technical Focus | Engineering Solution | Performance Benefit |

|---|---|---|

| Insulation & Materials | High-temp silicone & ceramic flame-retardant insulation | Up to 200°C endurance, UL94 V-0 flame rating |

| Connection & Sealing | Fully sealed, fool-proof HV connectors | IP67 protection, moisture & misplug prevention |

| EMC Design | 360° braided shielding + dual-end grounding | 30% EMI reduction, zero signal interference |

| Precision Process | Ultrasonic welding + automated crimping | 15% higher contact consistency |

| Quality Traceability | Full barcode trace system | Batch-level traceability for every component |

Through this systematic approach, Kehan has built a High Voltage Safety Architecture (HVSA) — a complete solution ensuring electrical, mechanical, and thermal safety for new-energy vehicles.

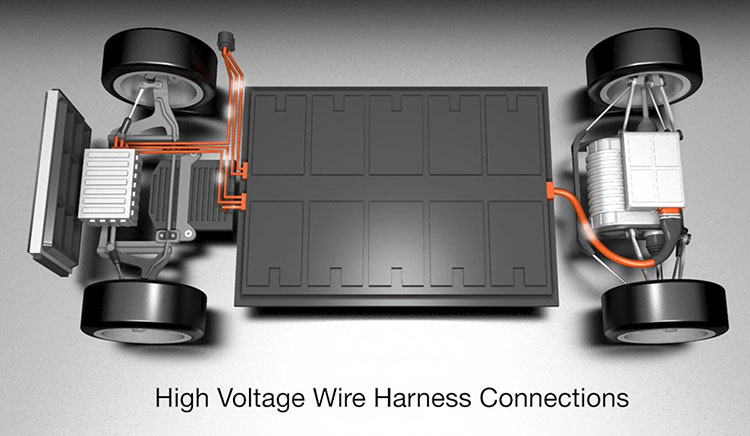

4. Case Study: The “Energy Artery” of an 800V SUV Platform

In 2024, a well-known EV manufacturer developing an 800V high-performance SUV faced strict design demands for its battery pack high-voltage harness assembly:

Must handle 900V voltage levels

Must meet IP67 protection & anti-vibration requirements

Must support 10-minute charging for 400 km range

Kehan’s engineers joined the design validation phase early, proposing a dual-layer silicone-insulated and shielded harness design with moisture-proof and fool-proof connector structures.

After extensive thermal shock and vibration testing, the harness assembly showed zero leakage or contact loosening, successfully passing vehicle-level validation.

As a result, the SUV model became one of the first mass-produced fast-charging vehicles in its category.

5. Industry Insight: The Hidden Race in High-Voltage Cable Engineering

As global EV penetration rises, high-voltage, lightweight, and intelligent harnesses define the future of power systems.

High-Voltage Evolution – Transitioning from 400V to 900V platforms for faster charging.

Lightweight Materials – Using aluminum conductors and composite shielding to reduce cable weight by 15%.

Smart Monitoring – Integrating temperature and current sensors for real-time harness diagnostics.

This means harness manufacturers are no longer “component suppliers” — they are strategic partners in vehicle safety architecture. Kehan’s technical vision perfectly aligns with this transformation.

6. Frequently Asked Questions (FAQ)

Q1: Can your high-voltage harnesses integrate with other brands’ connectors?

Yes. Kehan maintains long-term partnerships with JST and MOLEX, ensuring full compatibility with customer-specified connector models.

Q2: What are the maximum rated voltage and temperature?

Our harnesses support up to 1000V and continuous operation at 200°C, withstanding short-term thermal surges.

Q3: Do you support small-batch prototyping?

Absolutely. We provide rapid prototyping services with delivery in 3–5 working days.

Q4: How do you ensure consistent quality?

Each production line uses automated electrical testing with 100% inspection. Kehan is certified under ISO 9001:2015 and UL standards.

Q5: Do you offer design optimization services?

Yes. Our engineering team offers Design for Manufacturability (DfM) consultation to help customers reduce cost and improve assembly efficiency.

7. Conclusion: The Philosophy of Safe Energy Flow

The future of electric mobility depends on the safety and stability of every wire harness.

In the high-voltage ecosystem, these cables are not just conductors — they are the guardians of both performance and protection.

Kehan Electronics believes:

“Only when you treat the harness as part of the safety system — not an accessory —

can an electric vehicle truly go farther, faster, and safer.”

8. Call to Action

? Download the “EV High-Voltage Harness Design Checklist”

Learn the key design parameters and insulation strategies for high-voltage systems.

? Book a Free Technical Consultation

Let our engineers review your current harness design and provide professional optimization advice.

? Visit Us: www.xmkhwire.com

? Email: wireharness@xmkehan.com