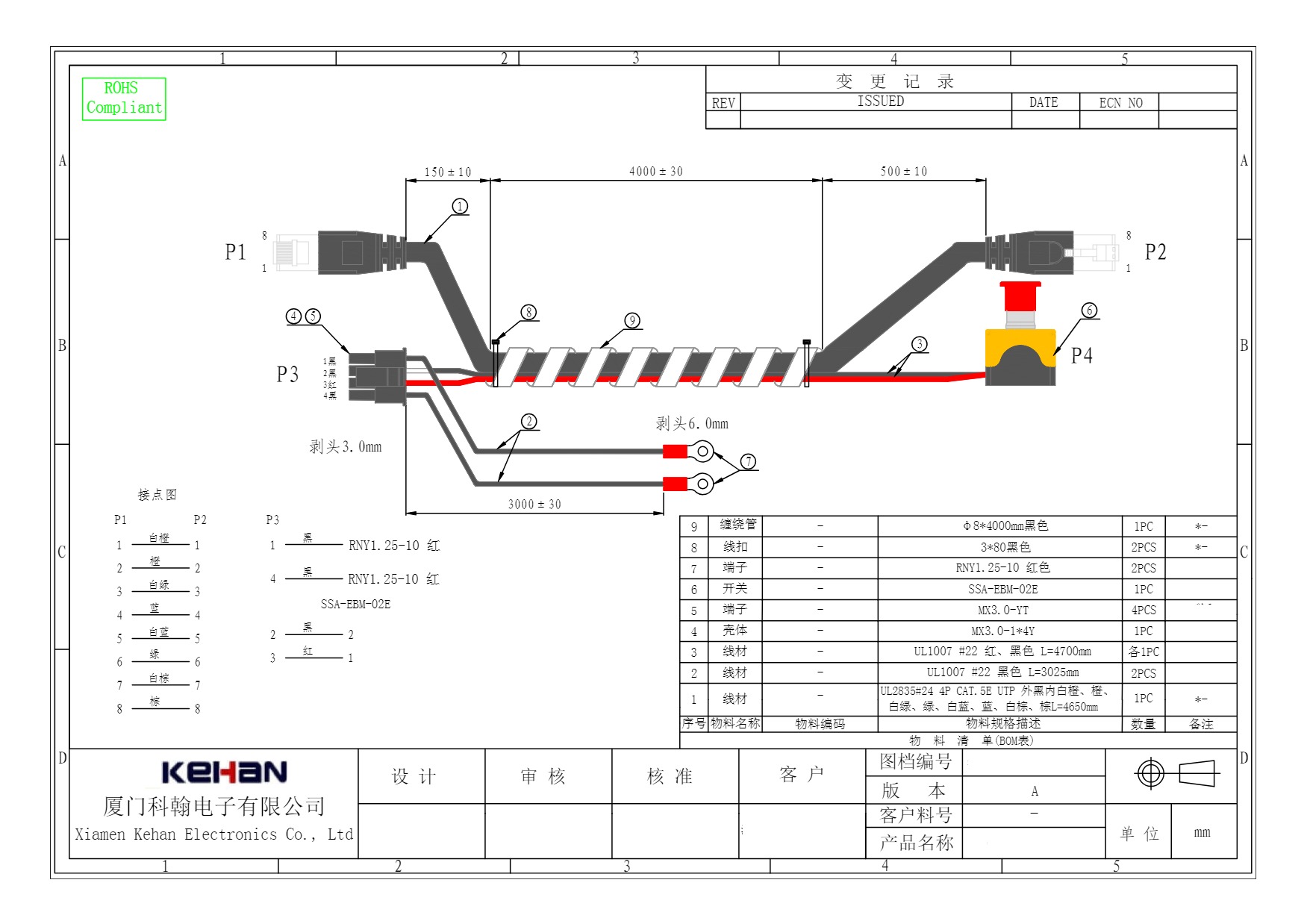

JST ZH PH EH XH Electronic Connectors 2/3/4/5/6 Pin Wire Harnesses with 1.0 1.25 1.5 2.0 2.54mm Pitch

We specialize in manufacturing high-performance, custom electronic wire harnesses tailored to your precise specifications. Our expertise encompasses both ultra-fine and standard pitch solutions, utilizing JST ZH, PH, EH, and XH series connectors for demanding 1.0mm pitch applications requiring miniaturization and reliability. For robust, general-purpose interconnect needs, we deliver durable 2.54mm pitch wire harnesses that ensure consistent signal and power transmission. Every assembly is crafted with high-quality PVC insulated wire harnesses, offering excellent flexibility, abrasion resistance, and electrical protection. From design to delivery, we guarantee harnesses that meet exact mechanical, environmental, and electrical requirements, ensuring seamless integration and long-term performance in your application. Trust us for precision, durability, and perfect connectivity.

- KeHan

- Xiamen City, Fujian Province, China

- 15-30days

- It can produce 5,000 pieces per day.

- Information

- Video

JST Connectors & 2.54mm Pitch Custom Solutions

We specialize in manufacturing high-performance, custom electronic wire harnesses tailored to your precise specifications. Our expertise encompasses both ultra-fine and standard pitch solutions, utilizing JST ZH, PH, EH, and XH series connectors for demanding 1.0mm pitch applications requiring miniaturization and reliability. For robust, general-purpose interconnect needs, we deliver durable 2.54mm pitch wire harnesses that ensure consistent signal and power transmission. Every assembly is crafted with high-quality PVC insulated wire harnesses, offering excellent flexibility, abrasion resistance, and electrical protection. From design to delivery, we guarantee harnesses that meet exact mechanical, environmental, and electrical requirements, ensuring seamless integration and long-term performance in your application. Trust us for precision, durability, and perfect connectivity.

Specification:

| Wire Type | VDE Cable,Dran Chain Cable, UL Wire,Medical Cable,ect. |

| Wire Size | 2AWG-32AWG,0.01mm2-50mm’ are available. |

| Wire Cores | 1 Core~50 cores are available. |

| Conductor | Bare Copper, Tinned copper, Silver Plated, Gold plated wire. |

| Rate Temperature | 80'C,105'C,125°C,180'C,220'C,300'C(176°F-572°F). |

| Protection | Waterproof, Low Smoke Halogen-Free, Anti-UV cable, Acid and alkali-resistant cable are available. |

| Certification | UL, VDE, CE IS0 or Customize Special Cables. |

| Raw materials | All parts and processing is compliant with ROHS,CCC. |

| Application | Electronics, intelligent robots, lighting, new energy, intelligent appliances. |

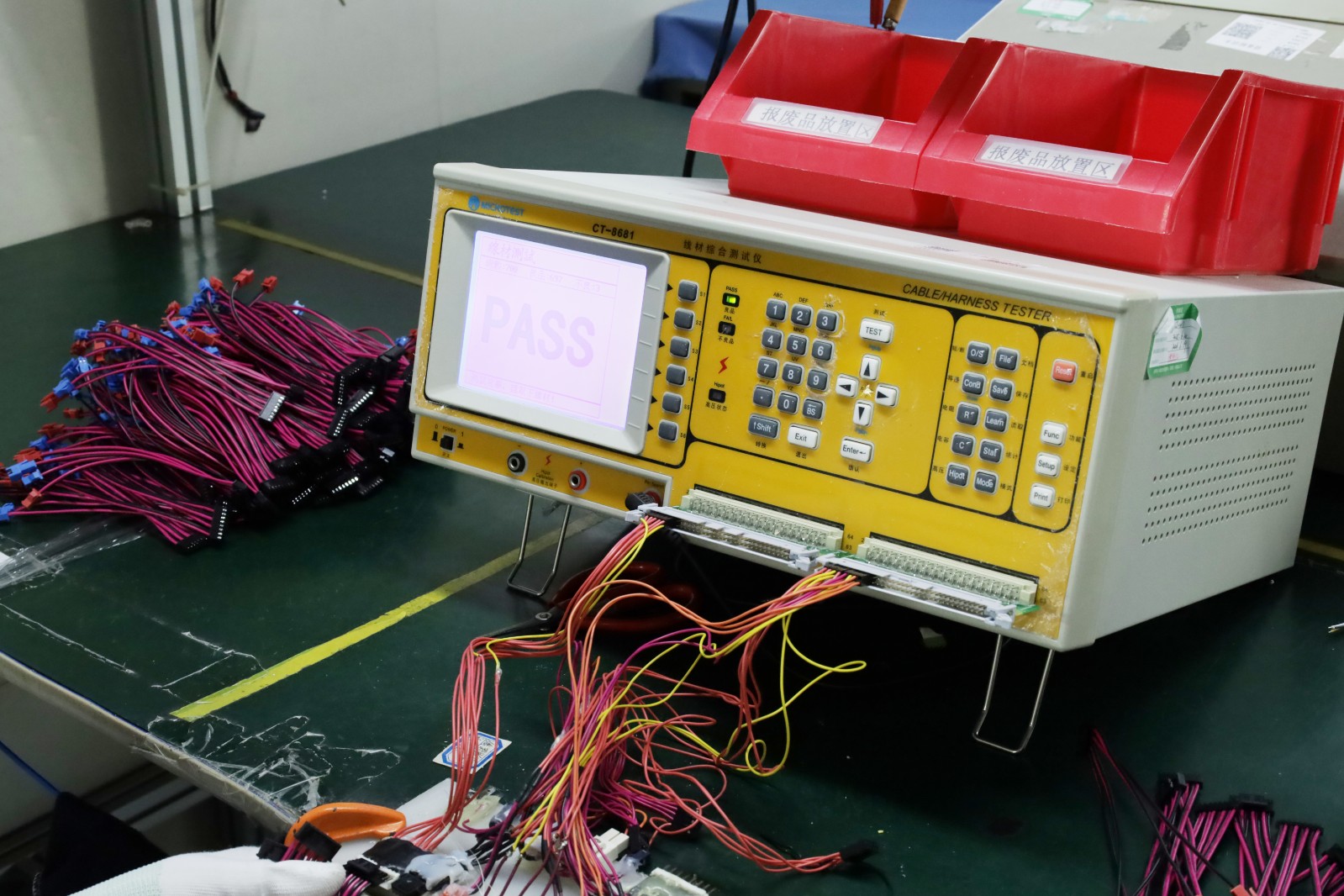

| Testing | 100% electrical performance tested before delivery. |

Advantage of Xiamen Kehan electric

For nearly two decades, XIamen kehan has been a leading provider of custom JST cable assembly manufacturing services in China. We specialize in delivering precision-engineered JST cable assemblies and comprehensive wire harness solutions to a global clientele across diverse industries.

As a dedicated cable assembly manufacturer, we work exclusively from customer-provided drawings and specifications to produce fully customized JST cable solutions. Our production facility is equipped with advanced automation and operates under a rigorous quality management system. This ensures that every cable assembly we manufacture complies with key international standards, including RoHS, UL, and IPC/WHMA-A-620.

Quality & Reliability | Innovation | Customer Commitment |

| Delivering precision-engineered wire harnesses, cable assemblies, and electro-mechanical assemblies that meet the highest industry standards. | We are committed to the continuous advancement of our processes and technologies, leveraging innovation to deliver state-of-the-art, tailored solutions for a wide range of industries. | We build enduring partnerships by listening deeply to your needs and delivering precisely engineered solutions. |

1:Please provide your design drawings, specifications, or samples.

2:We will review the drawings and provide you with the most competitive quote.

3:Upon your confirmation of the drawings and price, we can proceed with mass production or provide you with a sample first to ensure quality.

4:Finally, we will carefully package and ship your order promptly via the fastest available method.

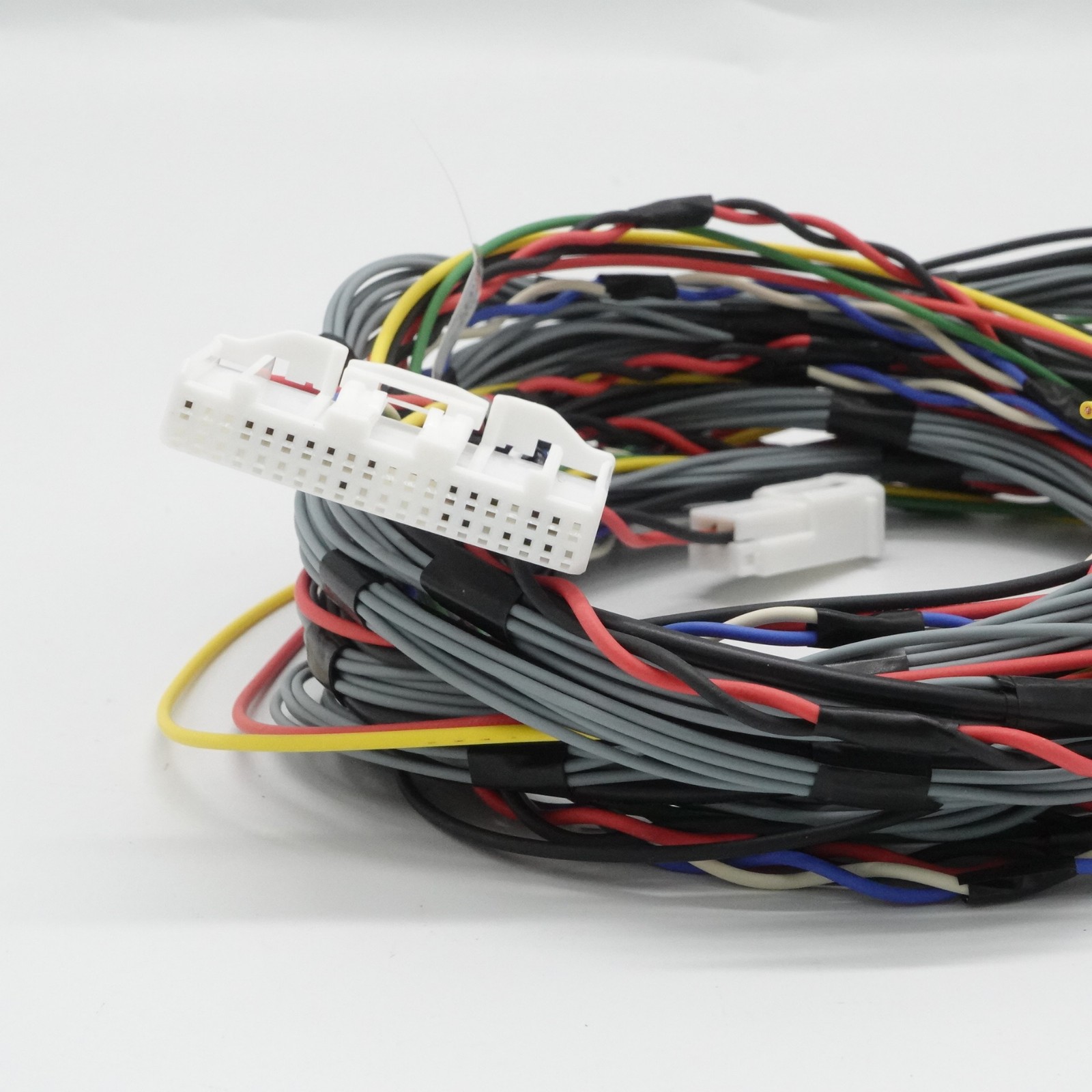

Customized products display

Communication wiring harness

Dust-proof wiring harness

Electrical equipment wiring harness

Welcome to visit our factory

Welcome to visit our factory

PWire harness production line

Injection molding machine

Terminal machine

Fully automatic wire cutting machine

Semi-automatic wire cutter

Wire Harness TEST EQUIPMENT

Aapplication area

Our wire harness solutions are widely used in:

Home Appliances

Agricultural Equipment

New Energy (e.g., EVs, charging systems)

Industrial Robotics

Consumer Electronics

Telecommunications

...and more.

Our key strengths are:

In-house factory for quality control and flexible production.

High customer collaboration to meet specific requirements.

Reliable service and responsive support.

High product quality with consistent performance.

OUR QUALIFICATIONS

FAQ

Q1:What is the purpose of a wire harness?

A:

1.Organization & Simplified Installation:

Q2:What is the typical lead time for OEM wire harness production?

A:Our lead times are structured to balance speed with precision: Prototype OEM wire harnesses are delivered within 2-3 weeks, thanks to our dedicated rapid prototyping cell. For production orders, standard lead time is 4-5 weeks. The exact timeline is influenced by factors including harness complexity, material availability, connector types, and order volume. We prioritize enhanced efficiency at every stage without compromising on quality.

Q3:What is your minimum order quantity for custom JST cable assemblies?

A:We accommodate both prototype development and high-volume production requirements for custom JST cables. Our minimum order quantities are flexible based on complexity and specifications, with prototype quantities starting from as few as 100 pieces.

For custom JST cable assembly development, we provide sample confirmation services before full production to ensure your specifications are met precisely. Our rapid prototyping capabilities help accelerate your product development timeline while maintaining manufacturing quality standards.