High Quality Connectors of Wiring Harness Pickup Truck 12 Circuit Wiring Harness Wire Kit Jst SM 2 Pin Connector

Our specialized JST SM 2 Pin Connector is engineered for precision and reliability, making it the ideal core component for custom Wiring Harness setups. Designed to ensure secure electrical connections, this connector supports durable and efficient Cable Assembly Jst integration across various applications. We provide tailored connectors of wiring harness that meet exact specifications, enhancing performance and compatibility. With a focus on quality and consistency, our harness solutions reduce assembly time and improve overall system reliability. Trust our expertise to deliver connectors and assemblies that combine durability, precise fit, and seamless connectivity for your unique projects.

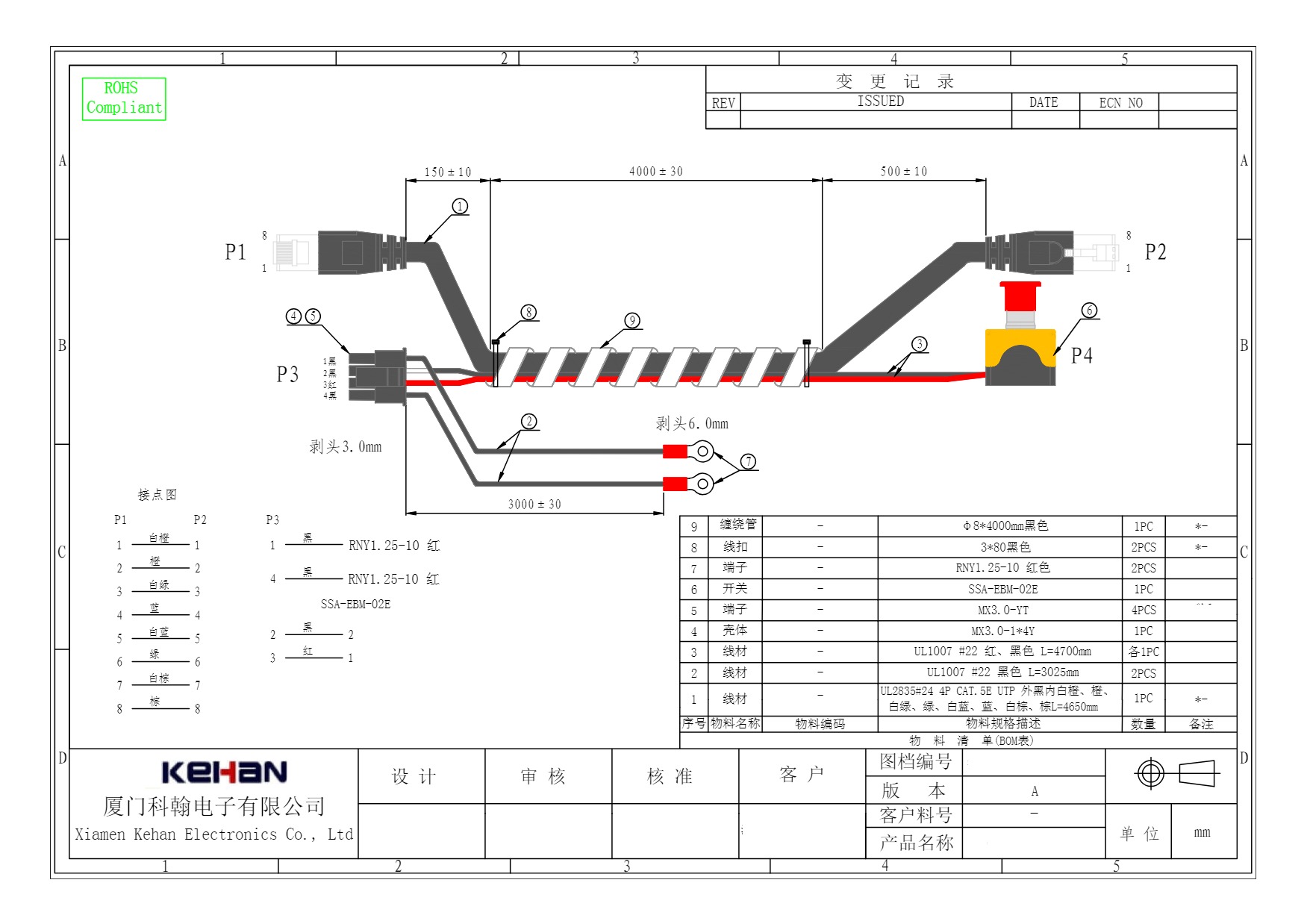

- KeHan

- Xiamen City, Fujian Province, China

- 15-30days

- It can produce 5,000 pieces per day.

- Information

- Video

Custom Wiring Harness & Cable Assembly Solutions

Our specialized JST SM 2 Pin Connector is engineered for precision and reliability, making it the ideal core component for custom Wiring Harness setups. Designed to ensure secure electrical connections, this connector supports durable and efficient Cable Assembly Jst integration across various applications. We provide tailored connectors of wiring harness that meet exact specifications, enhancing performance and compatibility. With a focus on quality and consistency, our harness solutions reduce assembly time and improve overall system reliability. Trust our expertise to deliver connectors and assemblies that combine durability, precise fit, and seamless connectivity for your unique projects.

Specification:

| Wire Type | VDE Cable,Dran Chain Cable, UL Wire,Medical Cable,ect. |

| Wire Size | 2AWG-32AWG,0.01mm2-50mm’ are available. |

| Wire Cores | 1 Core~50 cores are available. |

| Conductor | Bare Copper, Tinned copper, Silver Plated, Gold plated wire. |

| Rate Temperature | 80'C,105'C,125°C,180'C,220'C,300'C(176°F-572°F). |

| Protection | Waterproof, Low Smoke Halogen-Free, Anti-UV cable, Acid and alkali-resistant cable are available. |

| Certification | UL, VDE, CE IS0 or Customize Special Cables. |

| Raw materials | All parts and processing is compliant with ROHS,CCC. |

| Application | Electronics, intelligent robots, lighting, new energy, intelligent appliances. |

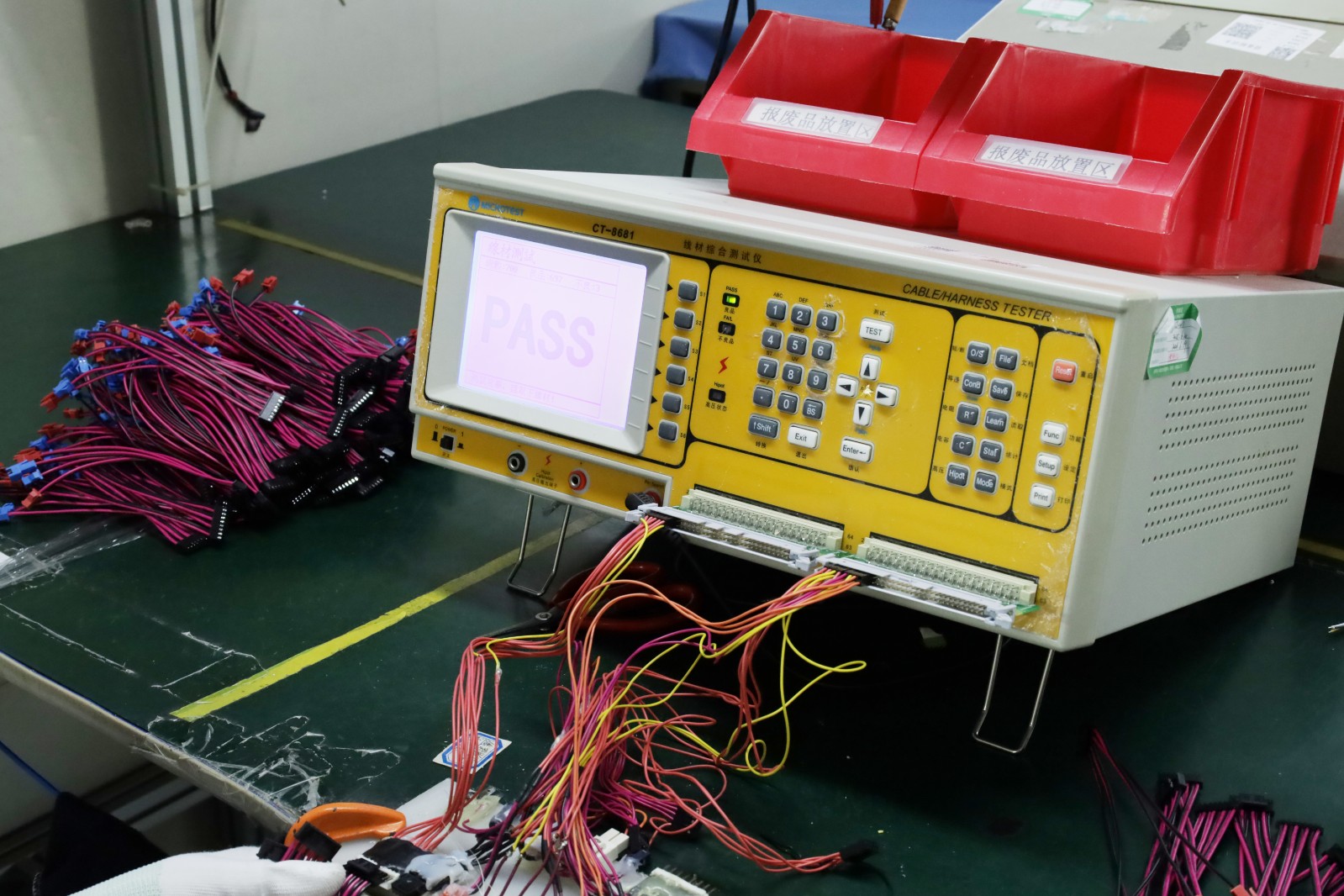

| Testing | 100% electrical performance tested before delivery. |

Advantage of Xiamen Kehan electric

For nearly two decades, XIamen kehan has been a leading provider of custom JST cable assembly manufacturing services in China. We specialize in delivering precision-engineered JST cable assemblies and comprehensive wire harness solutions to a global clientele across diverse industries.

As a dedicated cable assembly manufacturer, we work exclusively from customer-provided drawings and specifications to produce fully customized JST cable solutions. Our production facility is equipped with advanced automation and operates under a rigorous quality management system. This ensures that every cable assembly we manufacture complies with key international standards, including RoHS, UL, and IPC/WHMA-A-620.

Quality & Reliability | Innovation | Customer Commitment |

| Delivering precision-engineered wire harnesses, cable assemblies, and electro-mechanical assemblies that meet the highest industry standards. | We are committed to the continuous advancement of our processes and technologies, leveraging innovation to deliver state-of-the-art, tailored solutions for a wide range of industries. | We build enduring partnerships by listening deeply to your needs and delivering precisely engineered solutions. |

1:Please provide your design drawings, specifications, or samples.

2:We will review the drawings and provide you with the most competitive quote.

3:Upon your confirmation of the drawings and price, we can proceed with mass production or provide you with a sample first to ensure quality.

4:Finally, we will carefully package and ship your order promptly via the fastest available method.

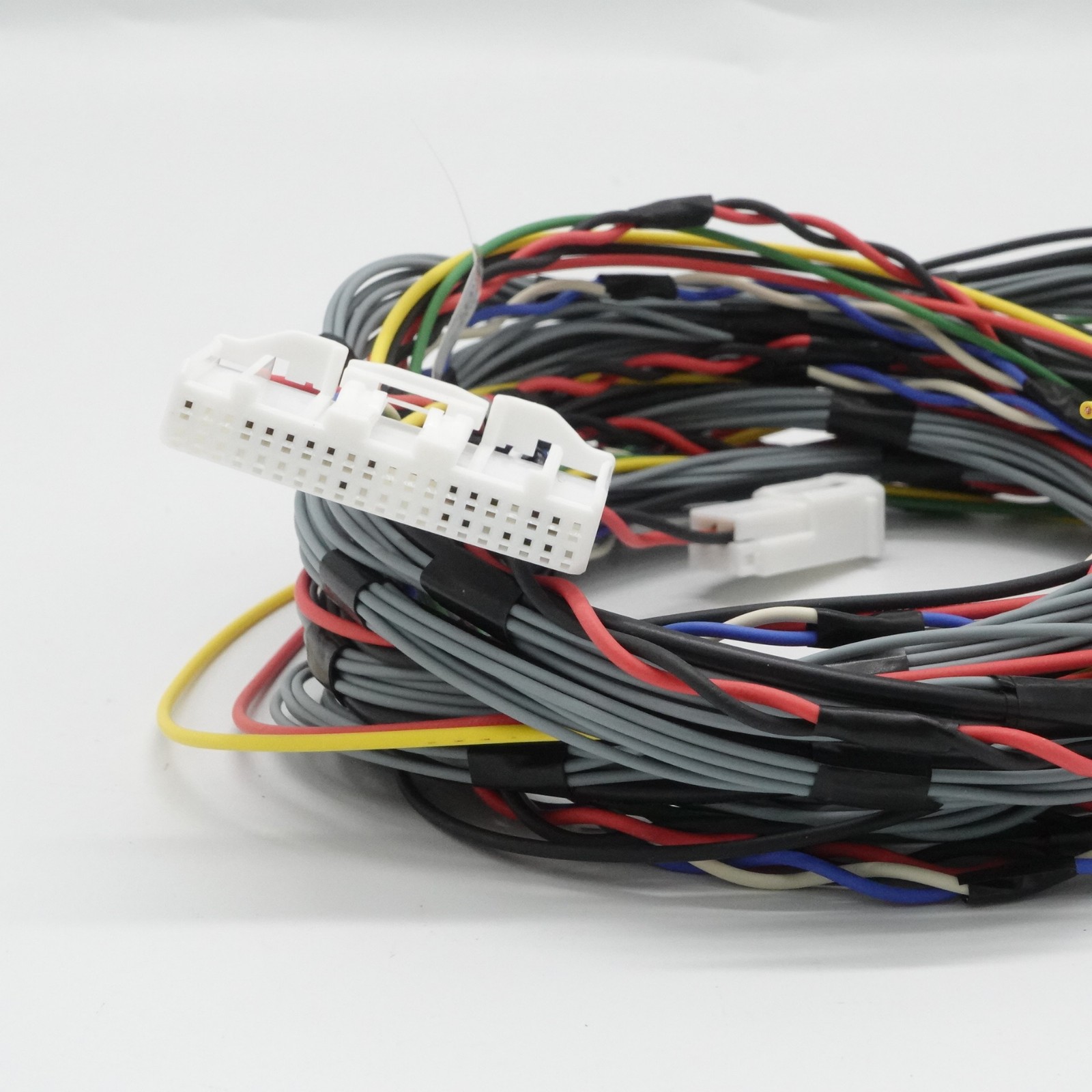

Customized products display

Communication wiring harness

Dust-proof wiring harness

Electrical equipment wiring harness

Welcome to visit our factory

Welcome to visit our factory

PWire harness production line

Injection molding machine

Terminal machine

Fully automatic wire cutting machine

Semi-automatic wire cutter

Wire Harness TEST EQUIPMENT

Aapplication area

Our wire harness solutions are widely used in:

Home Appliances

Agricultural Equipment

New Energy (e.g., EVs, charging systems)

Industrial Robotics

Consumer Electronics

Telecommunications

...and more.

Our key strengths are:

In-house factory for quality control and flexible production.

High customer collaboration to meet specific requirements.

Reliable service and responsive support.

High product quality with consistent performance.

OUR QUALIFICATIONS

FAQ

Q1:What is the purpose of a wire harness?

A: 1 Superior Miniaturization & Space Efficiency:

The defining feature of the SH series is its 1.0mm pitch, one of the finest in the standard JST catalog. Compared to common PH (2.0mm) or XH (2.5mm) series, the SH allows for a significantly higher number of connections in a limited footprint. This is critical for compact devices like smartphones, wearables, drones, ultra-thin laptops, and IoT sensor modules where internal space is at a premium.

2 Enhanced Reliability and Secure Connection:

Dual-Point Contact Design: The SH connector features a proprietary dual-contact terminal. This creates two stable contact points with the mating pin, reducing contact resistance, improving current stability, and providing redundancy against vibration and shock.

Positive Locking Mechanism: It incorporates a distinct tactile "click" upon full mating, provided by a secure latch. This prevents accidental disconnection due to movement or vibration, a vital feature for portable and industrial applications.

3 Optimized Electrical and Mechanical Performance:

Adequate Power Delivery: Despite its size, the SH connector is typically rated for 1A current, sufficient for most signal transmission and low-power applications (e.g., sensors, data lines, small LEDs).

High-Temperature Resilience: The housing is commonly made from heat-resistant LCP plastic, capable of withstanding IR reflow soldering temperatures (up to 260°C for 5-10 seconds), making it compatible with standard SMT assembly processes.

Flexibility and Routing Ease: SH assemblies typically use fine-gauge wires (e.g., AWG #28-30), resulting in a flexible cable that is easy to route in tight spaces without imposing excessive mechanical stress on solder joints.

4 Manufacturing and Assembly Advantages:

Automation-Friendly Design: The precision construction of SH connectors is ideal for automated pick-and-place, crimping, and assembly processes. This ensures high consistency, throughput, and cost-effectiveness in mass production.

Ready-to-Use Solution: As a pre-assembled cable harness, it eliminates the need for customers to invest in specialized crimping tools and manual assembly. This reduces production time, minimizes on-site errors, and lowers the total cost of ownership by simplifying the supply chain and assembly line workflow.

In summary, the JST SH cable assembly excels by delivering uncompromising connection reliability and electrical stability in an ultra-compact (1.0mm pitch) form factor. It serves as the essential "nervous system" for connecting high-density PCBs to internal modules, enabling the design of thinner, more modular, and more reliable electronic devices. For a custom wire harness manufacturer, highlighting these technical advantages demonstrates deep expertise in meeting the demands of advanced, miniaturized electronics.

Q2:What is JST SH connector?

A:The JST SH connector is a standardized, 1.0mm pitch wire-to-board connector system developed by Japan Solderless Terminal Mfg. Co., Ltd. It is a precision-engineered interconnective component designed for high-density, reliable circuitry within space-constrained modern electronics.

From a professional standpoint, its definition encompasses:

1 A System, Not Just a Part: It comprises a plastic housing (typically high-temperature LCP), a specific female terminal (usually phosphor bronze with tin plating), and a separate metal locking slider. This system is engineered for compatibility and assembly efficiency.

2 Distinctive Locking Mechanism: Its most recognizable feature is the side-actuated locking slider. After mating with the male header, the slider is engaged, producing an audible and tactile click. This positive lock provides exceptional resistance to vibration and accidental disconnection, a critical reliability factor.

3 Optimized Contact Physics: The terminal employs a dual-point contact design. This creates two parallel electrical paths with the male pin, ensuring lower and more stable contact resistance, redundancy, and superior performance under mechanical stress or micro-vibration.

4 Clear Application Niche: With its 1.0mm pitch and typical current rating of 1A per circuit, the SH series is explicitly designed for signal transmission and low-power distribution between PCBs, FPCs, or small internal modules. It is the industry-preferred solution for compact, lightweight devices where reliable connectivity in minimal space is paramount, such as smartphones, wearables, drones, and medical sensors.

In essence, the JST SH connector is a benchmark for miniaturized, mass-producible, and highly reliable interconnects in consumer and precision industrial electronics.

Q3:What is your minimum order quantity for custom JST cable assemblies?

A:We accommodate both prototype development and high-volume production requirements for custom JST cables. Our minimum order quantities are flexible based on complexity and specifications, with prototype quantities starting from as few as 100 pieces.

For custom JST cable assembly development, we provide sample confirmation services before full production to ensure your specifications are met precisely. Our rapid prototyping capabilities help accelerate your product development timeline while maintaining manufacturing quality standards.