Water Purifier Wiring Harness Factory

As a specialized Water Purifier Wiring Harness Factory, we provide comprehensive OEM wire harness solutions for diverse applications. Our expertise extends to producing precision LG washing machine harness components that meet original specifications, along with developing specialized custom wire harness systems for water purification equipment and other home appliances.

- KenHan

- Xiamen City, Fujian Province, China

- 3 ~ 4 weeks

- Information

- Video

As a specialized Water Purifier Wiring Harness Factory, we provide comprehensive OEM wire harness solutions for diverse applications. Our expertise extends to producing precision LG washing machine harness components that meet original specifications, along with developing specialized custom wire harness systems for water purification equipment and other home appliances.

As a specialized Water Purifier Wiring Harness Factory, we provide comprehensive OEM wire harness solutions for diverse applications. Our expertise extends to producing precision LG washing machine harness components that meet original specifications, along with developing specialized custom wire harness systems for water purification equipment and other home appliances.

Our manufacturing capabilities include:

Application-specific wiring solutions for water purifiers and major appliance brands

Complete custom harness design from concept to production

OEM-compliant manufacturing standards

Rigorous quality validation testing

We support both standardized and fully customized requirements, offering:

Durable materials suitable for moist environments

Precise connector compatibility

Optimized circuit configurations

Reliable performance under continuous operation

Trust our custom wire harness manufacturer expertise for reliable, safety-compliant wiring solutions. Contact us to discuss your specific wiring harness custom requirements and receive professional technical support.

Key Features & Benefits:

High-Conductivity Conductors: Utilizing 99.99% oxygen-free copper for high purity, low resistance, anti-aging properties, and extended service life. This ensures minimal energy loss, reduced heat generation, and superior current load capacity.

Durable Insulation & Sheathing: Made from environmental protection high-strength PVC or neoprene, offering excellent abrasion resistance, tensile strength, corrosion resistance, waterproofing, flame retardancy, oil resistance, and weather ability. Ideal for both indoor and outdoor use, even in harsh or moving environments.

Stringent Quality Control: Guarantees uniform thickness of insulation and sheath with very low eccentricity. Each harness undergoes high-voltage testing to ensure no breakdowns, providing ultimate safety and reliability.

Available Configurations: Choose from sheath colors including all black, white inner with orange outer, white inner with black outer, or white inner with blue outer.

Certifications & Testing: Our products comply with CCC, CE, ISO9001:2008, and ROHS standards. They have passed third-party tests for high-temperature resistance (105°C), low-temperature resistance (-40°C), and flame retardancy.

Common Specifications: Available in cross-sections from 10mm² to 120mm² (10mm, 16mm, 25mm, 35mm, 50mm, 70mm, 95mm, 120mm) to meet diverse power requirements.

Applications: Perfect for use as welding cable, torch wire, welding machine wire, battery cables, power leads for cutting tools, and grounding applications.

Request a free quote for your custom wiring harness needs and experience the difference in quality and performance!

Specification

| Wire Type | VDE Cable,Dran Chain Cable, UL Wire,Medical Cable,ect. |

| Wire Size | 2AWG-32AWG,0.01mm2-50mm’ are available. |

| Wire Cores | 1 Core~50 cores are available. |

| Conductor | Bare Copper, Tinned copper, Silver Plated, Gold plated wire. |

| Rate Temperature | 80'C,105'C,125°C,180'C,220'C,300'C(176°F-572°F). |

| Protection | Waterproof, Low Smoke Halogen-Free, Anti-UV cable, Acid and alkali-resistant cable are available. |

| Certification | UL, VDE, CE IS0 or Customize Special Cables. |

| Raw materials | All parts and processing is compliant with ROHS,CCC. |

| Application | Electronics, intelligent robots, lighting, new energy, intelligent appliances. |

| Testing | 100% electrical performance tested before delivery. |

Customizing the wiring harness only requires four steps!

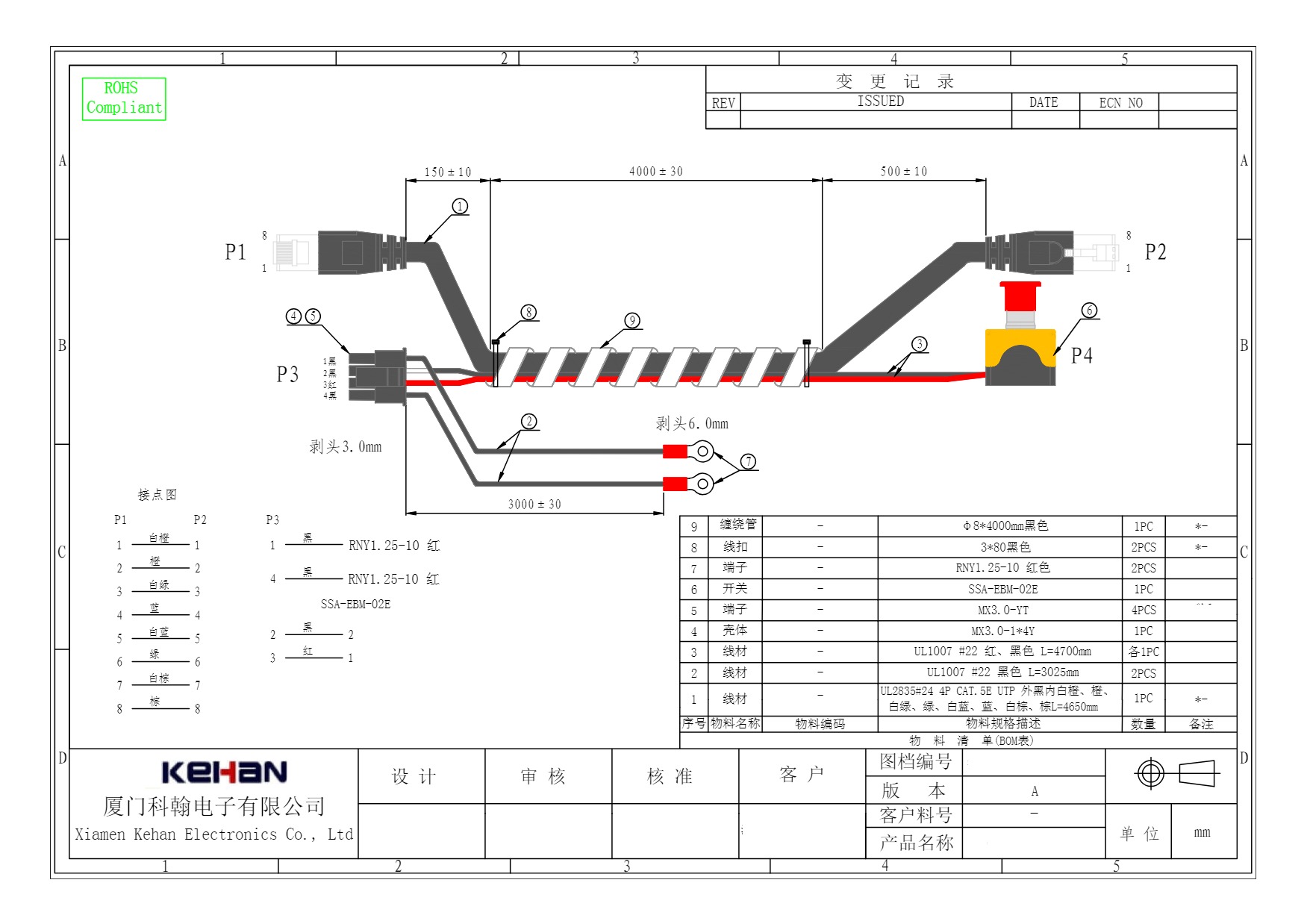

1:Please provide your design drawings, specifications, or samples.

2:We will review the drawings and provide you with the most competitive quote.

3:Upon your confirmation of the drawings and price, we can proceed with mass production or provide you with a sample first to ensure quality.

4:Finally, we will carefully package and ship your order promptly via the fastest available method.

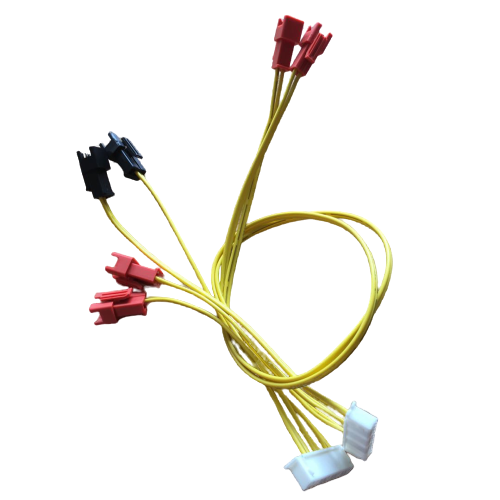

product display:

Our factory and production lines

FAQ

Q1:What should I look for in a reliable water purifier wiring harness factory?

A:A reliable water purifier wiring harness factory should prioritize quality control, compliance with industry standards, and customization capabilities. Look for factories with relevant certifications (e.g., ISO 9001, UL, or RoHS) to ensure product safety and performance. They should also offer end-to-end services, from design and prototyping to production and testing. Key factors include:

In-house testing labs for durability, electrical safety, and waterproofing (e.g., salt spray tests, load testing, and leakage checks) .

Experience in appliance wiring, particularly with water-related environments (e.g., moisture resistance and heat tolerance) .

Transparent communication and willingness to provide samples or factory audit reports.

Q2:How do I customize a water purifier wiring harness with a factory?

A:Customizing a water purifier wiring harness involves sharing specific requirements with the factory, including:

Electrical specifications: Voltage (e.g., 110V/220V), current load, and wire gauge (e.g., 16-22 AWG).

Connector types: Define connectors for pumps, sensors, or control boards (e.g., JST, Molex) .

Environmental needs: Materials rated for moisture resistance (e.g., PVC, TPE) or high-temperature insulation (up to 105°C) .

Safety standards: Ensure compliance with certifications like UL or IEC for leakage protection .

A reputable factory will use advanced design tools (e.g., CAD) to create prototypes and conduct rigorous tests (e.g., hipot testing) before mass production.

Q3:What are the common quality tests for water purifier wiring harnesses?

A:Factories perform multiple tests to ensure reliability:

Electrical Tests: Continuity checks, hipot (dielectric withstand), and insulation resistance tests to prevent short circuits or leakage .

Environmental Tests: Salt spray tests (for corrosion resistance), vibration tests (for durability), and waterproofing checks (e.g., IP67 ratings) .

Material Tests: Tensile strength checks for wires and thermal cycling to validate performance under temperature fluctuations.

Load Testing: Ensuring harnesses can handle peak current without overheating .

These tests align with international standards (e.g., IEC 60335) for appliance safety.

Q4:Why is material selection critical for water purifier wiring harnesses?

A:Water purifiers operate in humid or wet environments, making material choice vital for safety and longevity. Key considerations:

Insulation Materials: Use PVC, XLPE, or TPE for moisture resistance and flexibility .

Connectors: Prefer sealed or waterproof connectors (e.g., IP-rated) to prevent corrosion .

Conductors: Copper wires with tin plating to resist oxidation.

Substandard materials can lead to failures like insulation cracking, electrical leaks, or mold growth, risking device malfunction and user safety

Q5:How can a water purifier wiring harness factory help reduce costs without compromising quality?

A:A skilled factory can optimize costs through:

Value Engineering: Suggesting efficient designs (e.g., optimized wire lengths) or equivalent certified components.

Economies of Scale: Offering bulk pricing for large orders while maintaining quality.

Automated Production: Using automated crimping and testing to reduce labor costs and errors.

Material Sourcing: Leveraging partnerships for cost-effective, high-quality raw materials.

Ensure cost-cutting doesn’t sacrifice critical features like waterproofing or electrical safety certifications .