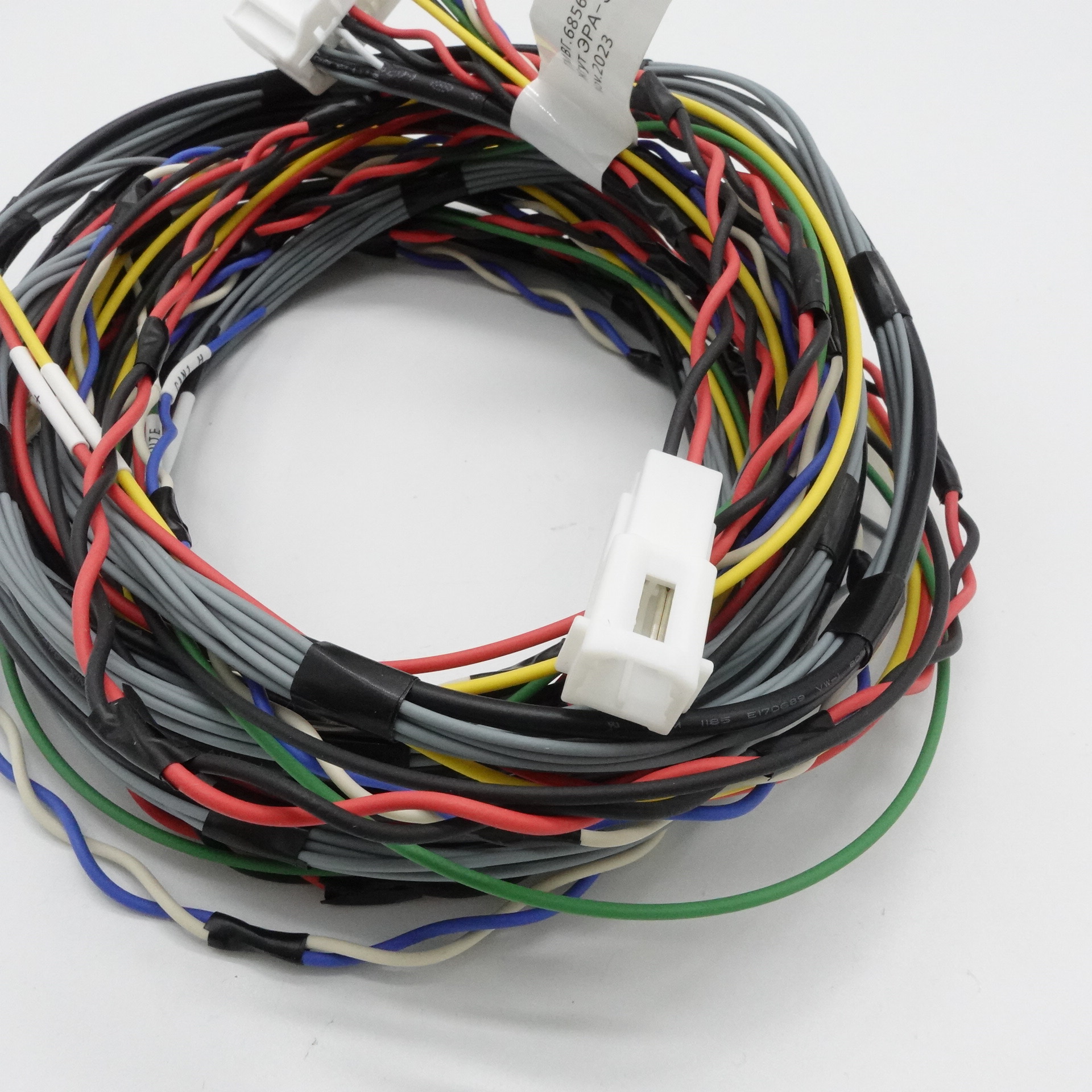

JST Wire Harness 1.0/1.25/1.5/2.0/2.54/3.96 mm JST Molex SH VH Electrical Wire Harness

We are a professional wire harness processing factory specializing in end-to-end custom wire harness manufacturing. Our core expertise lies in producing precision-engineered JST and Molex compatible wire harnesses, offering a wide range of standard pitch options (1.25mm to 6.5mm) including SH and VH series to meet diverse circuit board and device interconnection needs.

Our integrated wire harness fabrication service covers design, prototyping, and volume production. We ensure every cable wire harness assembly delivers flawless pin-to-wire accuracy, robust mechanical strength, and stable electrical performance for applications in automotive electronics, industrial controls, and consumer devices.

All products are built with certified materials and undergo rigorous electrical and mechanical validation. Partner with us for reliable OEM/ODM wire harness solutions that streamline your supply chain.

- KenHan

- Xiamen City, Fujian Province, China

- 3 ~ 4 weeks

- Information

- Video

We are a professional wire harness processing factory specializing in end-to-end custom wire harness manufacturing. Our core expertise lies in producing precision-engineered JST and Molex compatible wire harnesses, offering a wide range of standard pitch options (1.25mm to 6.5mm) including SH and VH series to meet diverse circuit board and device interconnection needs.

Our integrated wire harness fabrication service covers design, prototyping, and volume production. We ensure every cable wire harness assembly delivers flawless pin-to-wire accuracy, robust mechanical strength, and stable electrical performance for applications in automotive electronics, industrial controls, and consumer devices.

All products are built with certified materials and undergo rigorous electrical and mechanical validation. Partner with us for reliable OEM/ODM wire harness solutions that streamline your supply chain.

Key Features & Benefits:

High-Conductivity Conductors: Utilizing 99.99% oxygen-free copper for high purity, low resistance, anti-aging properties, and extended service life. This ensures minimal energy loss, reduced heat generation, and superior current load capacity.

Durable Insulation & Sheathing: Made from environmental protection high-strength PVC or neoprene, offering excellent abrasion resistance, tensile strength, corrosion resistance, waterproofing, flame retardancy, oil resistance, and weather ability. Ideal for both indoor and outdoor use, even in harsh or moving environments.

Stringent Quality Control: Guarantees uniform thickness of insulation and sheath with very low eccentricity. Each harness undergoes high-voltage testing to ensure no breakdowns, providing ultimate safety and reliability.

Available Configurations: Choose from sheath colors including all black, white inner with orange outer, white inner with black outer, or white inner with blue outer.

Certifications & Testing: Our products comply with CCC, CE, ISO9001:2008, and ROHS standards. They have passed third-party tests for high-temperature resistance (105°C), low-temperature resistance (-40°C), and flame retardancy.

Common Specifications: Available in cross-sections from 10mm² to 120mm² (10mm, 16mm, 25mm, 35mm, 50mm, 70mm, 95mm, 120mm) to meet diverse power requirements.

Applications: Perfect for use as welding cable, torch wire, welding machine wire, battery cables, power leads for cutting tools, and grounding applications.

Request a free quote for your custom wiring harness needs and experience the difference in quality and performance!

Specification

| Wire Type | VDE Cable,Dran Chain Cable, UL Wire,Medical Cable,ect. |

| Wire Size | 2AWG-32AWG,0.01mm2-50mm’ are available. |

| Wire Cores | 1 Core~50 cores are available. |

| Conductor | Bare Copper, Tinned copper, Silver Plated, Gold plated wire. |

| Rate Temperature | 80'C,105'C,125°C,180'C,220'C,300'C(176°F-572°F). |

| Protection | Waterproof, Low Smoke Halogen-Free, Anti-UV cable, Acid and alkali-resistant cable are available. |

| Certification | UL, VDE, CE IS0 or Customize Special Cables. |

| Raw materials | All parts and processing is compliant with ROHS,CCC. |

| Application | Electronics, intelligent robots, lighting, new energy, intelligent appliances. |

| Testing | 100% electrical performance tested before delivery. |

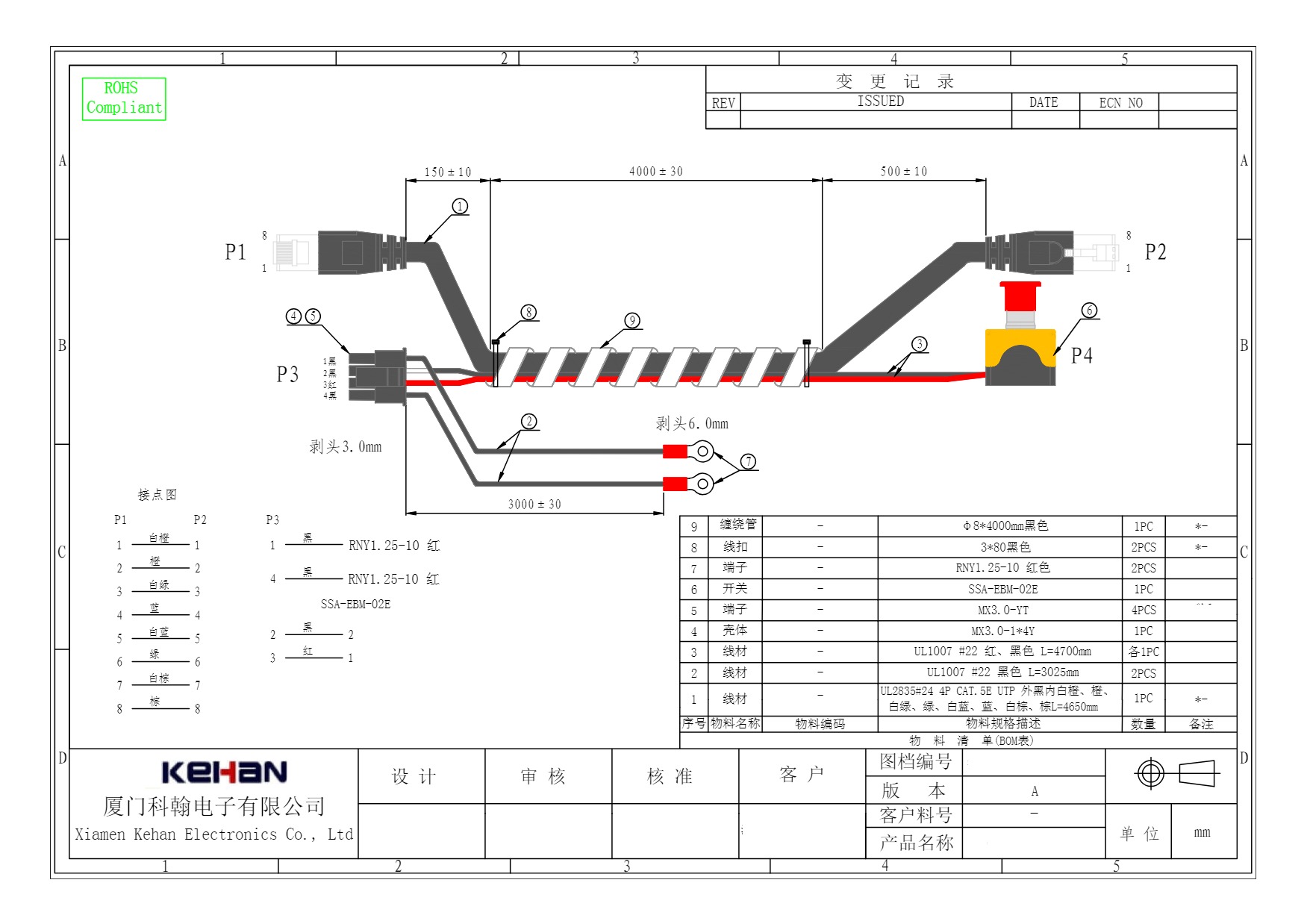

Customizing the wiring harness only requires four steps!

1:Please provide your design drawings, specifications, or samples.

2:We will review the drawings and provide you with the most competitive quote.

3:Upon your confirmation of the drawings and price, we can proceed with mass production or provide you with a sample first to ensure quality.

4:Finally, we will carefully package and ship your order promptly via the fastest available method.

product display:

Our factory and production lines

FAQ

Q1:What are common wire harness quality standards?

A:Key standards include UL for safety certification (e.g., UL 817), ISO 9001 for quality management systems, and IATF 16949 for the automotive sector. Specific performance standards like J-STD-001 govern soldering requirements, while IPC-WHMA-A-620 is the widely accepted industry standard for wire harness acceptance criteria.

Q2:What are the most common wiring harness problems?

A:Common issues include poor contact (short circuits, open circuits), connector issues (poor mating, oxidation), physical wire damage (cut strands, insulation abrasion), improper routing causing stress, and substandard manufacturing like faulty crimps or soldering, all of which can lead to system failures

Q3:What causes a wire harness to fail?

A:Failures stem from manufacturing defects (poor crimping, faulty connectors), physical damage (crushing, chafing), environmental stress (vibration, temperature cycles, moisture leading to oxidation), electrical overload, and improper installation or repair