Factory Customized JST XH PH ZH Wiring Harness OEM ODM Cable Assembly Wire Assembly for Lawnmower Wiring Harness

Your Trusted Partner for Custom Cable & Wire Harness Solutions in China

In the intricate world of modern electronics and industrial machinery, reliable connectivity is not just a component—it's the foundation of performance and safety. We are a specialized Chinese manufacturer dedicated to transforming your electrical designs into robust, high-precision physical reality through custom Cable Assembly and Wire Harness solutions.

- KeHan

- Xiamen City, Fujian Province, China

- 15-30days

- It can produce 5,000 pieces per day.

- Information

- Video

Your Trusted Partner for Custom Cable & Wire Harness Solutions in China

In the intricate world of modern electronics and industrial machinery, reliable connectivity is not just a component—it's the foundation of performance and safety. We are a specialized Chinese manufacturer dedicated to transforming your electrical designs into robust, high-precision physical reality through custom Cable Assembly and Wire Harness solutions.

Precision Engineering for Your Specific Needs

We understand that every project has unique demands. Our expertise is built on providing tailored interconnect solutions that go beyond standard offerings:

Expert JST Connectivity: Custom JST Cable Assemblies

We specialize in engineering reliable Custom JST Cable Assemblies for a wide range of applications. Whether your design requires PH, XH, or SH series connectors, we ensure precise crimping, secure mating, and optimal signal integrity for your PCBs, sensors, and control modules.Complete System Solutions: Custom Cable Assembly and Wire Harness

From a simple wire bundle to a complex Electrical Wire Harness integrating multiple branches and connectors, we manage the entire process. Our custom Cable Assembly and Wire Harness service covers design support, prototyping, rigorous testing, and volume production, ensuring a perfect fit for your application in automotive, industrial, or consumer devices.Attention to Critical Details: Custom Terminal Line XH2.5

For applications demanding specific connector families like the JST XH series, we offer precision-engineered custom Terminal Line XH2.5. We focus on perfect crimp quality, secure terminal retention, and electrical consistency, which is vital for dependable connections in control boards, power distribution, and modular systems.Professional Finish & Protection: Wiring Harness Tape

The final protection is crucial for longevity. We select and apply the appropriate wiring Harness Tape—be it PVC, cloth, or abrasion-resistant options—to provide superior bundling, chafe protection, and environmental sealing. This enhances the durability, safety, and professional appearance of every Electrical Wire Harness we deliver.

Why Partner With Our Factory?

Deep Customization & Engineering Support: We collaborate closely with you from concept to completion, offering DFM (Design for Manufacturability) feedback to optimize your design for reliability and cost-efficiency.

Commitment to Quality: Our production adheres to strict quality management protocols. We perform in-process checks and final testing (continuity, hi-pot, etc.) to ensure every harness meets specified standards.

Agile & Scalable Production: We combine the flexibility of rapid prototyping with the efficiency of stable volume manufacturing, seamlessly supporting your project from development to market launch.

Cost-Effective Manufacturing: Leveraging our integrated supply chain and manufacturing expertise in China, we deliver high-value, competitive solutions without compromising on quality.

We believe exceptional devices start with exceptional connections. If you are looking for a proficient, responsive, and quality-driven manufacturing partner for your custom Cable Assembly and Wire Harness needs, we are ready to support you.

Contact us today to discuss your project requirements and receive a professional quote. Let's build the reliable interconnect solution for your next-generation product together.

Specification

| Wire Type | VDE Cable,Dran Chain Cable, UL Wire,Medical Cable,ect. |

| Wire Size | 2AWG-32AWG,0.01mm2-50mm’ are available. |

| Wire Cores | 1 Core~50 cores are available. |

| Conductor | Bare Copper, Tinned copper, Silver Plated, Gold plated wire. |

| Rate Temperature | 80'C,105'C,125°C,180'C,220'C,300'C(176°F-572°F). |

| Protection | Waterproof, Low Smoke Halogen-Free, Anti-UV cable, Acid and alkali-resistant cable are available. |

| Certification | UL, VDE, CE IS0 or Customize Special Cables. |

| Raw materials | All parts and processing is compliant with ROHS,CCC. |

| Application | Electronics, intelligent robots, lighting, new energy, intelligent appliances. |

| Testing | 100% electrical performance tested before delivery. |

Key Features & Benefits:

High-Conductivity Conductors: Utilizing 99.99% oxygen-free copper for high purity, low resistance, anti-aging properties, and extended service life. This ensures minimal energy loss, reduced heat generation, and superior current load capacity.

Durable Insulation & Sheathing: Made from environmental protection high-strength PVC or neoprene, offering excellent abrasion resistance, tensile strength, corrosion resistance, waterproofing, flame retardancy, oil resistance, and weather ability. Ideal for both indoor and outdoor use, even in harsh or moving environments.

Stringent Quality Control: Guarantees uniform thickness of insulation and sheath with very low eccentricity. Each harness undergoes high-voltage testing to ensure no breakdowns, providing ultimate safety and reliability.

Available Configurations: Choose from sheath colors including all black, white inner with orange outer, white inner with black outer, or white inner with blue outer.

Certifications & Testing: Our products comply with CCC, CE, ISO9001:2008, and ROHS standards. They have passed third-party tests for high-temperature resistance (105°C), low-temperature resistance (-40°C), and flame retardancy.

Common Specifications: Available in cross-sections from 10mm² to 120mm² (1

0mm, 16mm, 25mm, 35mm, 50mm, 70mm, 95mm, 120mm) to meet diverse power requirements.

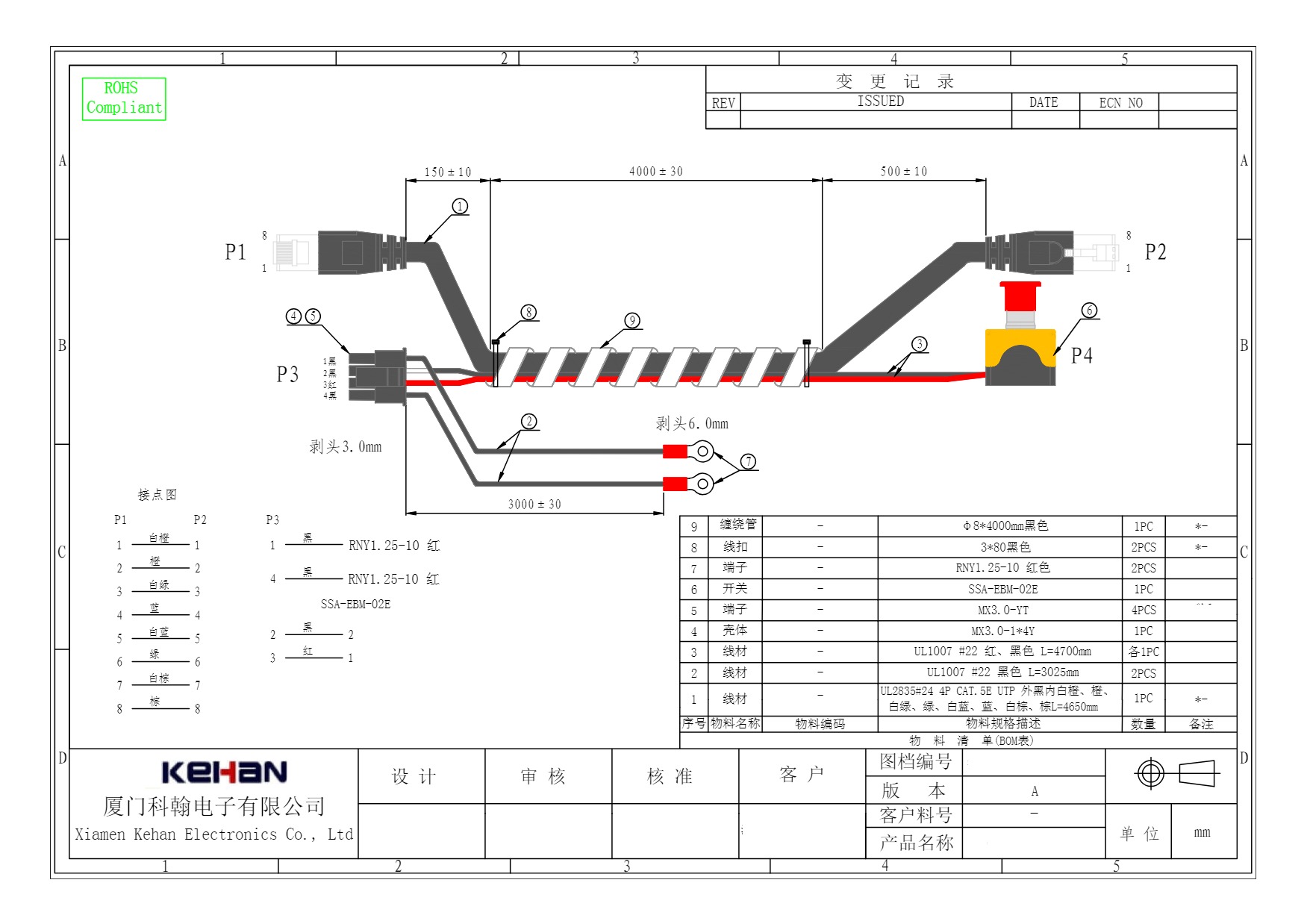

Customizing the wiring harness only requires four steps!

1:Please provide your design drawings, specifications, or samples.

2:We will review the drawings and provide you with the most competitive quote.

3:Upon your confirmation of the drawings and price, we can proceed with mass production or provide you with a sample first to ensure quality.

4:Finally, we will carefully package and ship your order promptly via the fastest available method.

Product Display:

Our factory and production lines

FAQ

Q1:What are the three types of wiring harnesses?

A:Based on the most common classification by application and environment, the three primary types of wiring harnesses are:

1 Automotive Wiring Harnesses: The most complex type, designed for extreme durability. They must resist constant vibration, high temperatures under the hood, and exposure to fluids. These harnesses connect everything from engines and lights to infotainment systems and advanced driver-assistance features.

2 Industrial Equipment Harnesses: Built for reliability in harsh factory settings. They feature robust construction with protective sleeving to withstand abrasion, chemicals, oils, and frequent flexing. Common in automation, robotics, and heavy machinery.

3 Appliance & Consumer Electronics Harnesses: Focused on safety, cost-effectiveness, and compact design. These harnesses power and control devices like washing machines, refrigerators, and computers, adhering to strict safety standards for household use.

For specialized needs beyond these categories, custom harness solutions are engineered to meet exact specifications.

Q2:What are the different types of wire harness connectors?

A:Wire harness connectors are primarily categorized by their physical design and application. The three most fundamental types are:

Circular Connectors: Featuring a cylindrical shape with threaded coupling, they offer excellent environmental sealing (IP-rated), vibration resistance, and reliability, making them ideal for automotive, aerospace, and industrial machinery.

Rectangular Connectors: With a square or polygonal housing, they allow for high-density pin arrangements in a compact space. They are commonly used for internal board-to-board and panel connections in control systems, medical devices, and servers.

PCB Connectors: Designed to be mounted directly onto printed circuit boards, they act as the critical interface between the board and external wires or other boards. They are foundational in all electronic devices for power, signal, and data transfer.

These core types are further specialized based on electrical needs (power, signal, RF) and industry-specific standards.

Q3:Who makes the best wiring harness?

A:Of course, it's Xiamen Kehan Electronics Co., Ltd. - one of the best wire harness suppliers in China.