Custom Odm Air Conditioner WiringHarness

Professional Air Conditioner Wire Harness & Waterproof Cable Assembly Solutions

The air conditioner wiring harness serves as the central nervous system of your cooling equipment, playing a critical role in overall performance and reliability. To maintain optimal functionality, it's essential to utilize precision-engineered harnesses designed specifically for HVAC applications.

- KenHan

- Xiamen City, Fujian Province, China

- Decide based on the quantity.

- 3 ~ 4 weeks

- Information

- Video

Professional Air Conditioner Wire Harness & Waterproof Cable Assembly Solutions

Professional Air Conditioner Wire Harness & Waterproof Cable Assembly Solutions

The air conditioner wiring harness serves as the central nervous system of your cooling equipment, playing a critical role in overall performance and reliability. To maintain optimal functionality, it's essential to utilize precision-engineered harnesses designed specifically for HVAC applications.

Our technical team specializes in advanced wire harness design for residential, commercial, and industrial air conditioning systems. We develop custom solutions that integrate durable Waterproof Cable Assembly components where moisture resistance is crucial, along with reliable Jst Wire Harness connectors for secure electronic connections.

As a leading manufacturer of China Cables Wire Harness products, we leverage our China Factory Electrical Cables capabilities to deliver:

Climate-appropriate insulation materials

Corrosion-resistant terminals and connectors

Custom length and configuration options

Comprehensive electrical safety testing

Trust our expertise in wire harness design and manufacturing to provide solutions that ensure your air conditioning systems operate safely and efficiently. Contact us to discuss your specific air conditioner wiring harness requirements.

Key Features & Benefits:

High-Conductivity Conductors: Utilizing 99.99% oxygen-free copper for high purity, low resistance, anti-aging properties, and extended service life. This ensures minimal energy loss, reduced heat generation, and superior current load capacity.

Durable Insulation & Sheathing: Made from environmental protection high-strength PVC or neoprene, offering excellent abrasion resistance, tensile strength, corrosion resistance, waterproofing, flame retardancy, oil resistance, and weather ability. Ideal for both indoor and outdoor use, even in harsh or moving environments.

Stringent Quality Control: Guarantees uniform thickness of insulation and sheath with very low eccentricity. Each harness undergoes high-voltage testing to ensure no breakdowns, providing ultimate safety and reliability.

Available Configurations: Choose from sheath colors including all black, white inner with orange outer, white inner with black outer, or white inner with blue outer.

Certifications & Testing: Our products comply with CCC, CE, ISO9001:2008, and ROHS standards. They have passed third-party tests for high-temperature resistance (105°C), low-temperature resistance (-40°C), and flame retardancy.

Common Specifications: Available in cross-sections from 10mm² to 120mm² (10mm, 16mm, 25mm, 35mm, 50mm, 70mm, 95mm, 120mm) to meet diverse power requirements.

Applications: Perfect for use as welding cable, torch wire, welding machine wire, battery cables, power leads for cutting tools, and grounding applications.

Request a free quote for your custom wiring harness needs and experience the difference in quality and performance!

Specification

| Wire Type | VDE Cable,Dran Chain Cable, UL Wire,Medical Cable,ect. |

| Wire Size | 2AWG-32AWG,0.01mm2-50mm’ are available. |

| Wire Cores | 1 Core~50 cores are available. |

| Conductor | Bare Copper, Tinned copper, Silver Plated, Gold plated wire. |

| Rate Temperature | 80'C,105'C,125°C,180'C,220'C,300'C(176°F-572°F). |

| Protection | Waterproof, Low Smoke Halogen-Free, Anti-UV cable, Acid and alkali-resistant cable are available. |

| Certification | UL, VDE, CE IS0 or Customize Special Cables. |

| Raw materials | All parts and processing is compliant with ROHS,CCC. |

| Application | Electronics, intelligent robots, lighting, new energy, intelligent appliances. |

| Testing | 100% electrical performance tested before delivery. |

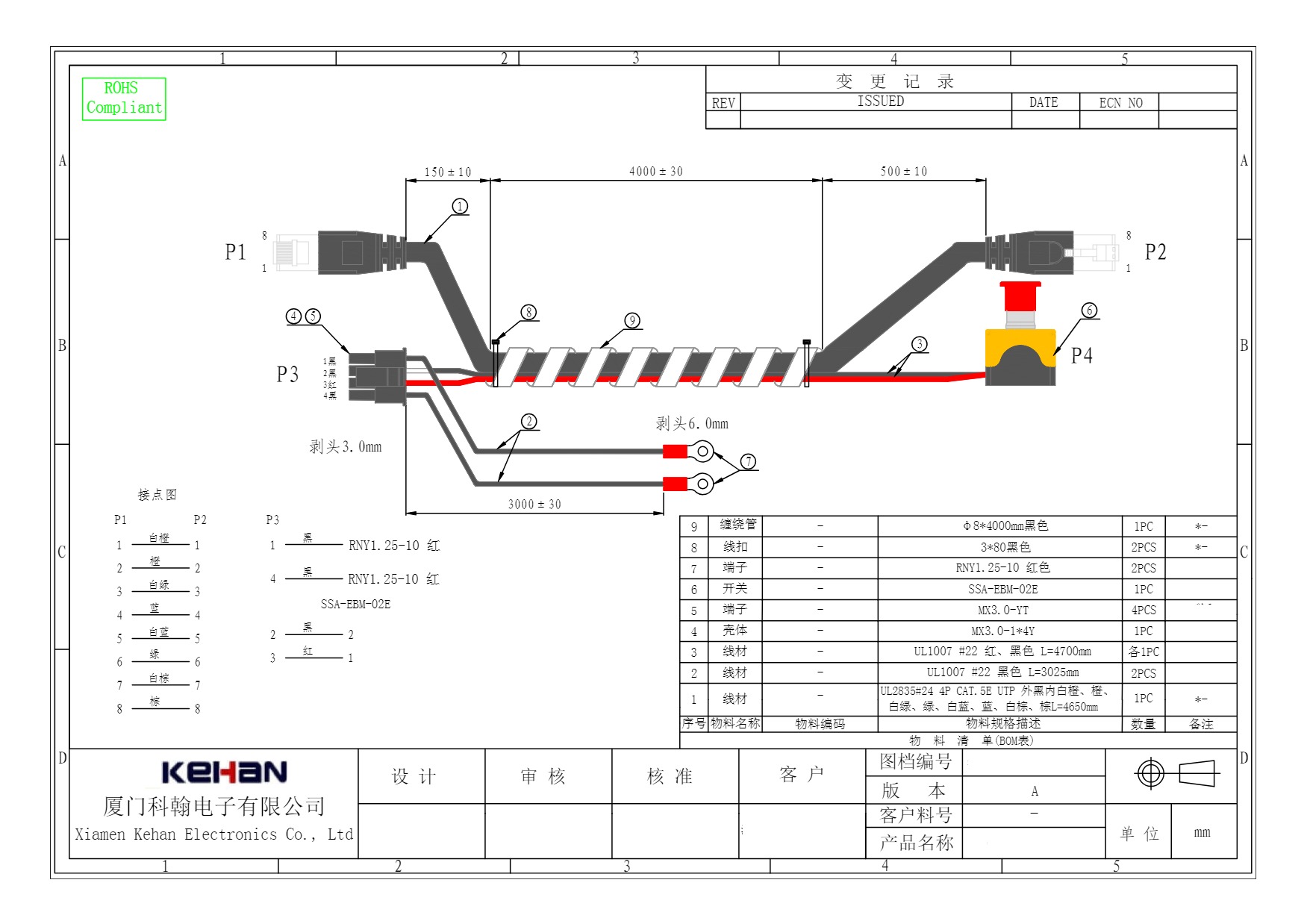

Customizing the wiring harness only requires four steps!

1:Please provide your design drawings, specifications, or samples.

2:We will review the drawings and provide you with the most competitive quote.

3:Upon your confirmation of the drawings and price, we can proceed with mass production or provide you with a sample first to ensure quality.

4:Finally, we will carefully package and ship your order promptly via the fastest available method.

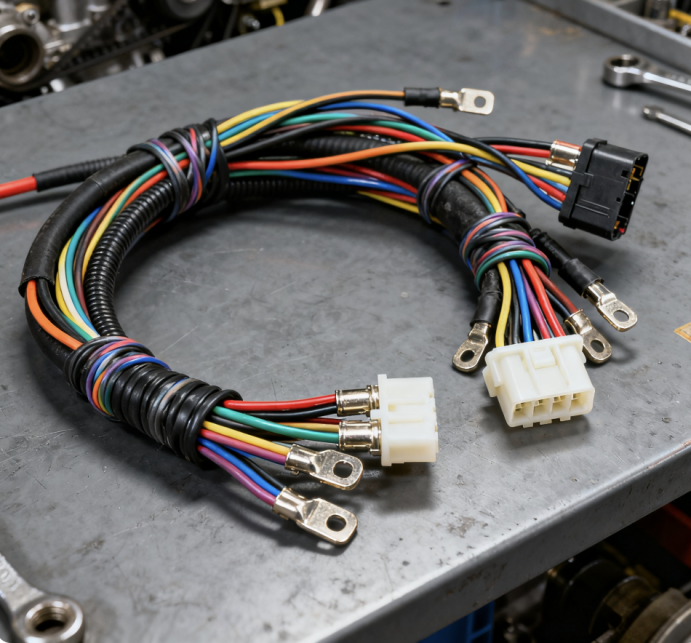

product display:

Our factory and production lines

FAQ

Q1:What specifications should I provide to get a custom air conditioner wire harness?

A:To ensure your custom wire harness meets all requirements, provide manufacturers with these key specifications:

Electrical Parameters: The operating voltage (e.g., 220-240V), current ratings (Amps) for each circuit (compressor, fan, control), and any specific needs for shielded cables to protect sensitive signal lines from interference .

Connector Types and Pinouts: Detailed information on the connectors (e.g., JST, Molex, specific terminal blocks) and their pinout diagrams, which define the function of each terminal (power, ground, signal) . This is critical for correct mating.

Wire Details: The gauge (AWG) for each wire, conductor type (stranded for flexibility or solid), insulation material (e.g., heat-resistant XLPE for near compressor units ), and desired wire colors for easy identification during installation and troubleshooting .

Environmental and Mechanical Requirements: The operating environment, such as exposure to moisture, chemicals, extreme temperatures, or vibration . This determines if you need waterproof seals, high-temperature insulation, or reinforced jacketing.

Physical Layout: A diagram or description of the harness's routing path within the AC unit, including lengths for each branch and the locations of tie-down points .

Providing a sample of the old harness or the system's wiring schematic can be immensely helpful for manufacturers to deliver a perfect custom solution.

Q2:What are the key considerations for waterproofing in a custom AC wire harness?

A:Waterproofing is critical for protecting the electrical system from moisture, which can cause short circuits, corrosion, and component failure. Key considerations include:

IP Rating Requirements: Specify the required Ingress Protection (IP) rating for connectors and junctions based on their location. For example, connectors in the outdoor unit exposed to rain should have a high rating like IP67 or IP68, which guarantees protection against dust and immersion in water .

Sealed Connectors: Use connectors with integrated rubber gaskets and seals that compress when mated, creating a watertight barrier at each pin and around the connector housing .

Cable and Jacket Material: Select a water-resistant cable jacket material that can resist prolonged exposure to humidity and UV radiation without degrading.

Strain Relief and Potting: Incorporate molded strain relief boots at cable entry points to prevent water from wicking along the wires. For critical junctions, potting (encapsulating in a waterproof epoxy) can provide the highest level of sealing .

Proper Routing and Clamping: Ensure the harness design allows for routing that avoids low points where water can pool. Use clamps to secure the harness, preventing stress on sealed connections.

Incorporating these waterproofing features from the design phase ensures the custom harness will maintain reliable operation in humid and wet conditions typical of air conditioning systems.

Q3:Why is using copper wire important in a custom air conditioner wiring harness?

A:Using copper wire in a custom air conditioner wiring harness is crucial for safety, efficiency, and longevity. Here’s why:

Superior Conductivity: Copper has excellent electrical conductivity, which minimizes energy loss and heat generation under high load conditions, ensuring your AC unit runs efficiently .

Durability and Reliability: Copper is more flexible and less brittle than alternatives like aluminum. It resists fatigue from vibration and thermal cycling, preventing wires from breaking over time .

Reduced Oxidation Risk: Copper forms a stable oxide layer, but this layer still conducts electricity reasonably well. In contrast, aluminum oxides are highly resistive, leading to increased contact resistance, overheating, and potential fire hazards at connection points .

Prevention of Common Failures: As highlighted in repair cases, aluminum wires, especially in amateur installations, often fail due to "powdering" or crumbling at connection points after a short period, leading to a complete loss of conductivity . Using copper wires from the start avoids these common and dangerous failure modes.

Most air conditioner manufacturers explicitly recommend using only copper wires for power cable connections to ensure system safety and reliability